CHALLENGES

Struggling with unusable metal powder?

Dealing with out-of-spec metal powder presents several practical problems:

Increased Costs

Each process leaves behind powder that can't be reused. You have powder but you have to buy new powder to carry on your work.

Storage and Handling

Unusable powder still takes up space and requires proper storage and handling with safety measures in mind.

Printout quality

Using mix of powders for AM processes due to unavailability of required alloy in powder form brings out concerns about final part quality.

Disposal Concerns

Time Waste

Managing and testing leftover powder to see if it’s still usable consumes valuable time. If testing reveals the powder is out-of-spec, it further delays work, as fresh powder needs to be sourced and tested.

“Currently, no atomization methods are available that can directly utilize titanium powder, as feedstock. Recycling of powder is done by returning it to primary metallurgical processes, which incurs high costs due to both the processing itself and the logistics of handling flammable powder. But we have the solution for that and it’s called POWDER-TO-POWDER device.”

“Currently, no atomization methods are available that can directly utilize titanium powder, as feedstock. Recycling of powder is done by returning it to primary metallurgical processes, which incurs high costs due to both the processing itself and the logistics of handling flammable powder. But we have the solution for that and it’s called POWDER-TO-POWDER device.”

“Currently, no atomization methods are available that can directly utilize titanium powder, as feedstock. Recycling of powder is done by returning it to primary metallurgical processes, which incurs high costs due to both the processing itself and the logistics of handling flammable powder. But we have the solution for that and it’s called POWDER-TO-POWDER device.”

LIMITATIONS

CURRENT PARTIAL SOLUTIONS

So far there has been no perfect solution to recycle small and medium powder batches. Current solutions help, but they have limitations.

01

Plasma Spheroidization

Plasma spheroidization is a thermal process where irregular, deformed, or fragmented powder particles are melted in a plasma jet, causing them to reform into spherical shapes. This method improves flowability and restores uniform particle size distribution. Additionally, the process can homogenize the internal structure of the particles by eliminating defects formed during initial processing. It's particularly useful for recovering powders that have altered particle morphology or suffered thermal degradation.

However, plasma spheroidization only changes particle shape to make it spherical. It cannot change particle size or homogenize mix of powders.

02

Sieving and Classification

To address changes in particle size distribution, a sieving and classification system can be employed. This involves separating the usable particles from fines, overspray, or sintered particles. By using precise mesh sizes, you can refine the particle distribution to meet desired specifications, ensuring a uniform size range. While this won't restore degraded powder or improve flowability directly, it helps recover a portion of the powder that still meets specifications.

However, sieving and classification don't improve flowability. It only separates particles based on size but doesn't address issues like poor flowability or internal defects caused by thermal degradation or irregular morphology.

03

Atomization for Re-powderization

In the case of materials with altered particle morphology or inconsistent properties, re-atomization can be the only way to recycle the powder. During this process, the material is melted and atomized again, producing a new batch of powder with homogeneous internal structure and uniform particle size. This process enhances flowability and reduces waste by transforming even deformed or oversized particles into fine, spherical ones that meet industrial standards.

However, atomization processes require specific feedstock forms for efficient operation – usually rod or wire. As a result, the unusable powder needs excessive reprocessing to convert it into suitable feedstock form before it can be atomized again making the whole process costly and time-consuming.

LIMITATIONS

CURRENT PARTIAL SOLUTIONS

So far there has been no perfect solution to recycle small and medium powder batches. Currennt solutions help, but they have limitations.

01

Plasma Spheroidization

Plasma spheroidization is a thermal process where irregular, deformed, or fragmented powder particles are melted in a plasma jet, causing them to reform into spherical shapes. This method improves flowability and restores uniform particle size distribution. Additionally, the process can homogenize the internal structure of the particles by eliminating defects formed during initial processing. It's particularly useful for recovering powders that have altered particle morphology or suffered thermal degradation.

02

Sieving and Classification

To address changes in particle size distribution, a sieving and classification system can be employed. This involves separating the usable particles from fines, overspray, or sintered particles. By using precise mesh sizes, you can refine the particle distribution to meet desired specifications, ensuring a uniform size range. While this won't restore degraded powder or improve flowability directly, it helps recover a portion of the powder that still meets specifications.

03

Atomization for Re-powderization

In the case of materials with altered particle morphology or inconsistent properties, re-atomization can be the only way to recycle the powder. During this process, the material is melted and atomized again, producing a new batch of powder with homogeneous internal structure and uniform particle size. This process enhances flowability and reduces waste by transforming even deformed or oversized particles into fine, spherical ones that meet industrial standards.

However, plasma spheroidization only changes particle shape to make it spherical. It cannot change particle size or homogenize mix of powders.

However, sieving and classification don't improve flowability. It only separates particles based on size but doesn't address issues like poor flowability or internal defects caused by thermal degradation or irregular morphology.

However, atomization processes require specific feedstock forms for efficient operation – usually rod or wire. As a result, the unusable powder needs excessive reprocessing to convert it into suitable feedstock form before it can be atomized again making the whole process costly and time-consuming.

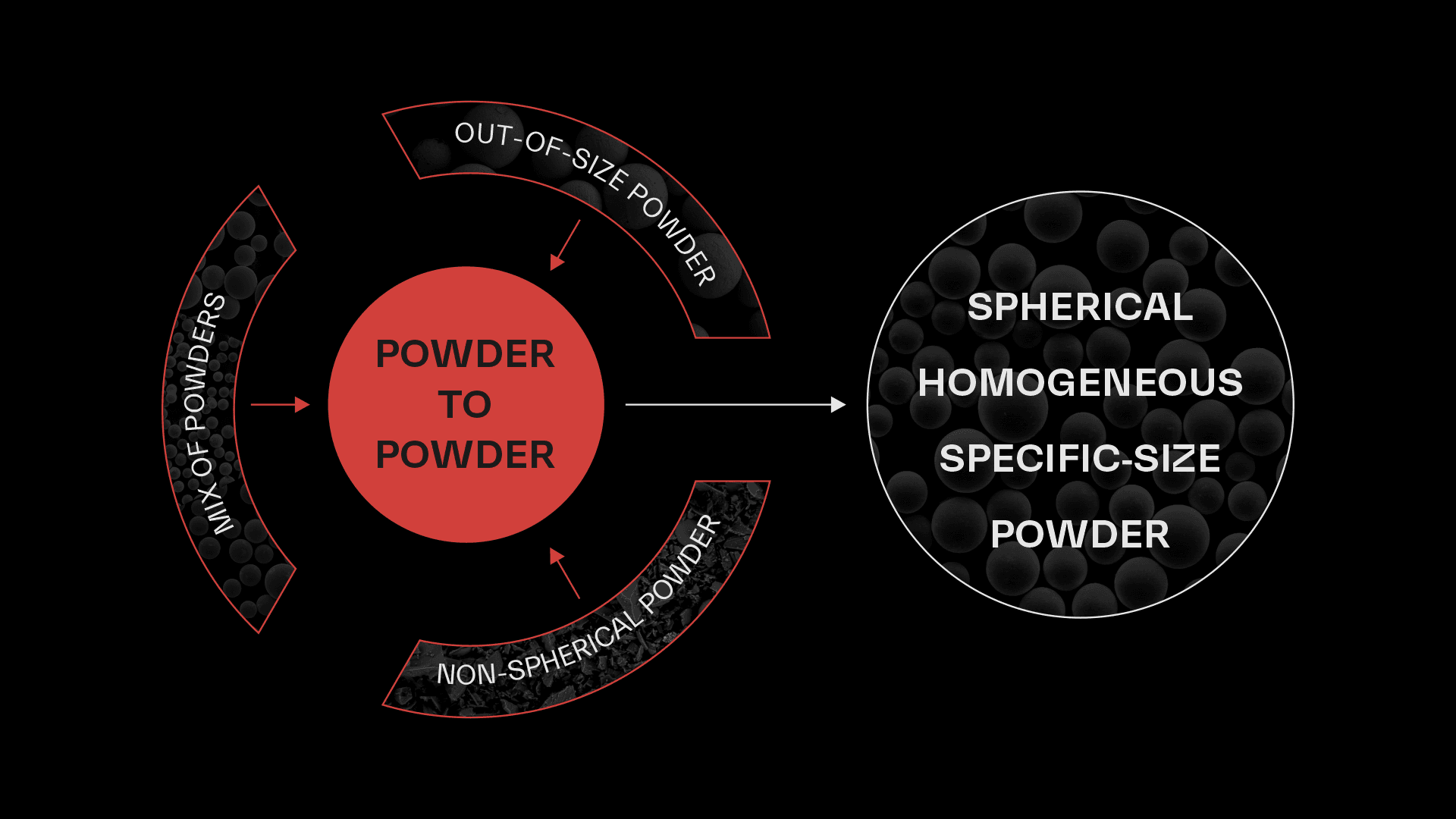

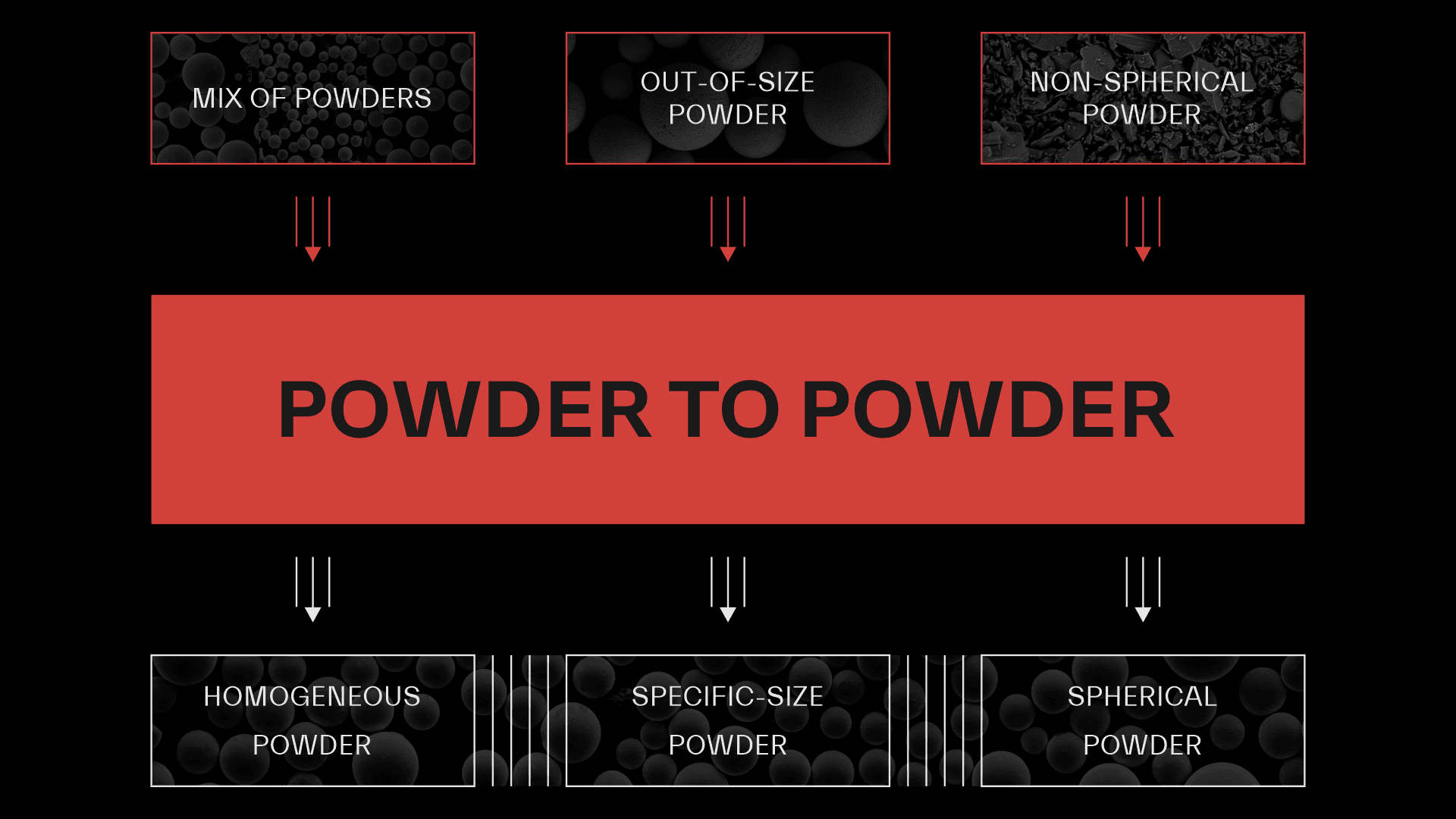

POWDER-TO-POWDER

BENEFITS & FEATURES

BENEFITS & FEATURES

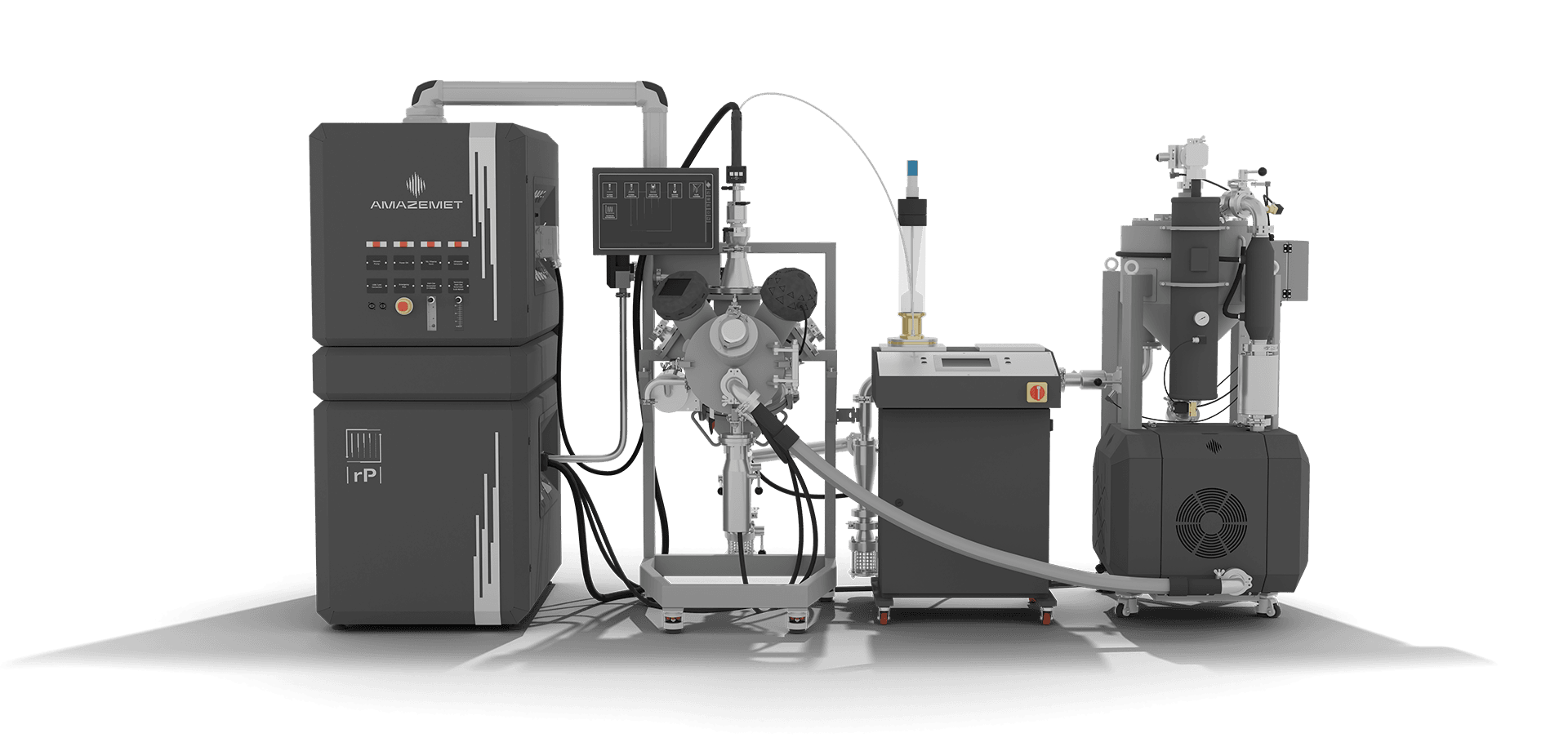

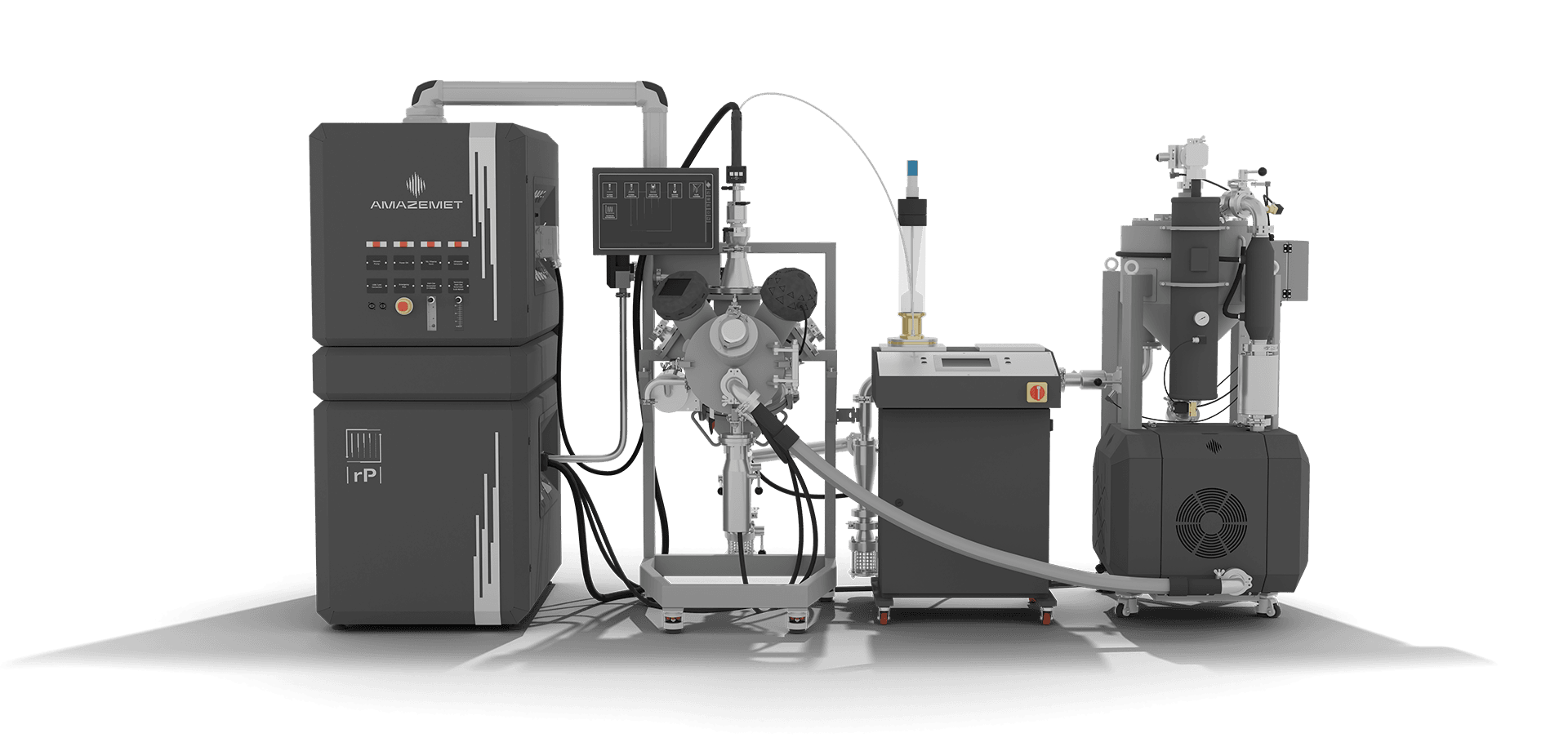

With our cutting-edge solution, managing metal powder becomes seamless. Our all-in-one device enables a continuous, closed-loop production process, regardless of the input powder quality, delivering high-quality powder output every time.

With our cutting-edge solution, managing metal powder becomes seamless. Our all-in-one device enables a continuous, closed-loop production process, regardless of the input powder quality, delivering high-quality powder output every time.

Reduced powder costs and purchase procedures

buy powder once and reuse it until it’s fully consumed, cutting expenses and increasing operational efficiency.

Reduced powder waste disposal

reuse powder instead of disposing it, minimizing waste and environmental impact.

Closed-loop production chain

Integrate recycling and reuse into your production process for a sustainable, cost-effective solution.

Custom powders from the scrap you already have

mix unused powder to get new alloy composition with homogeneous powder particles.

Metal research multitool

Single device for metal powder production from various feedstock forms, now including also high-efficiency atomization of metal powder.

New research possibilities

Take your research to the next level by utilizing recycled materials and exploring innovative applications.

ANIMATION

Novel Powder2Powder technology

MATERIAL

MS1

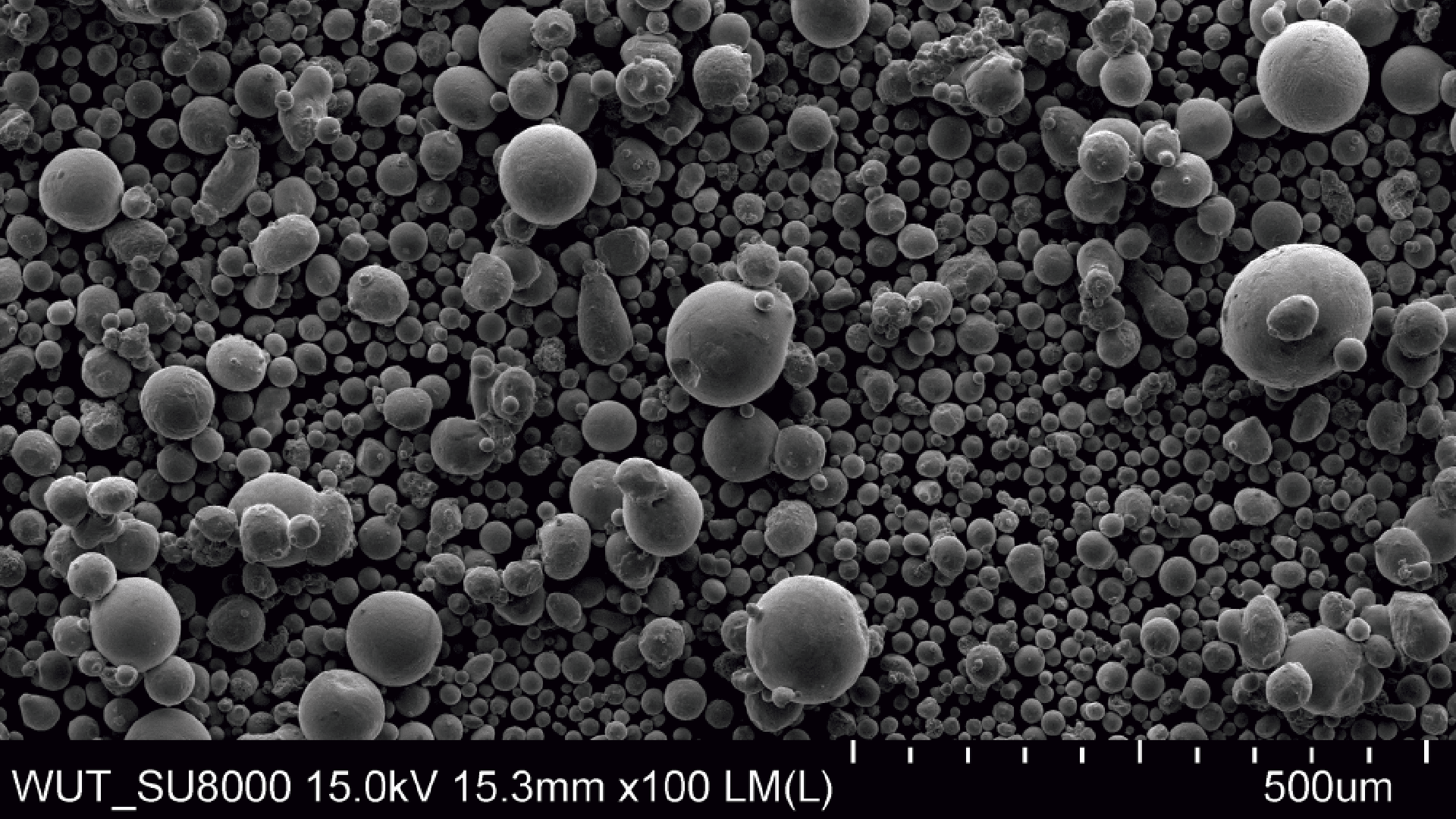

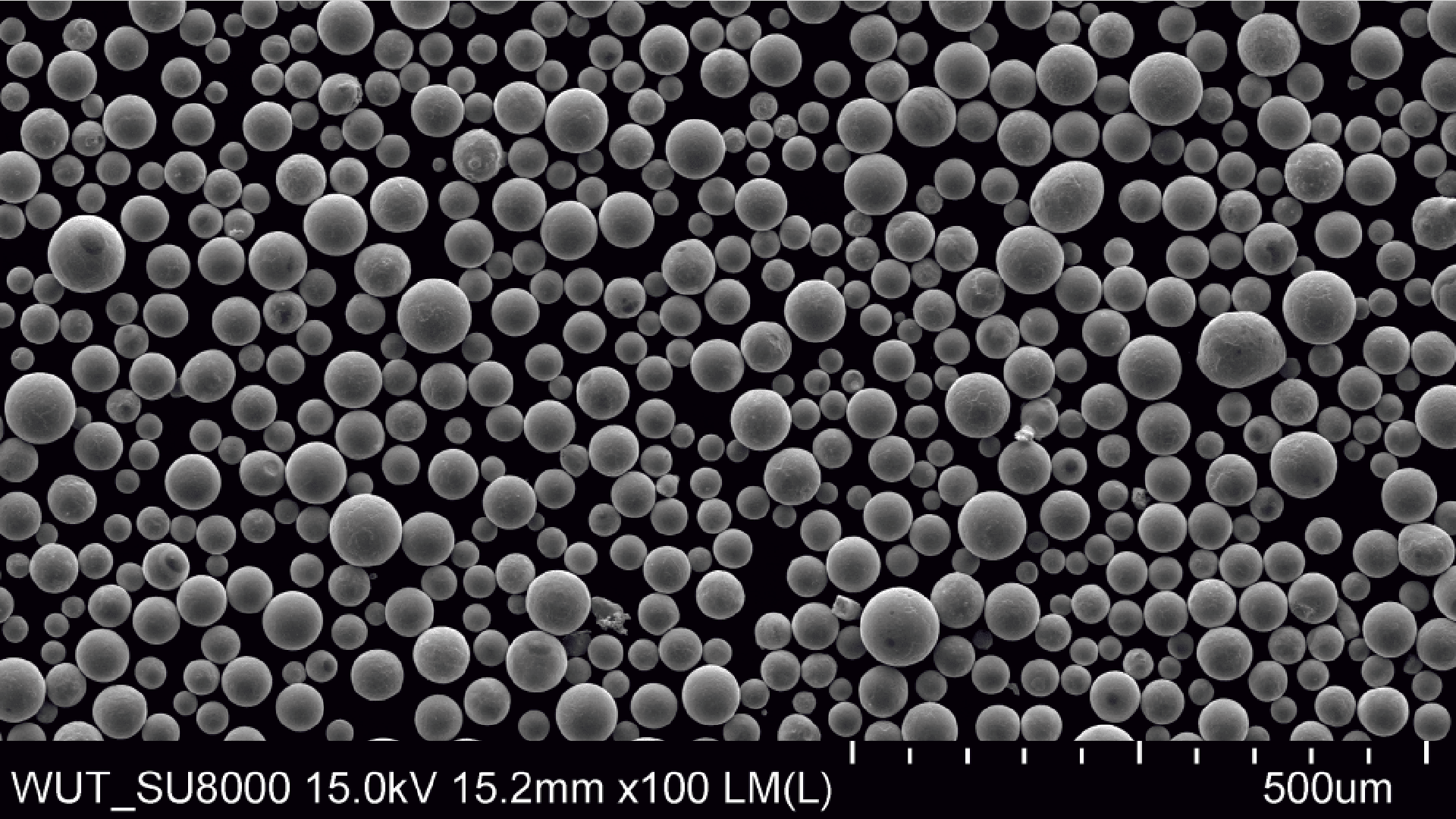

Is your metal powder

out of spec?

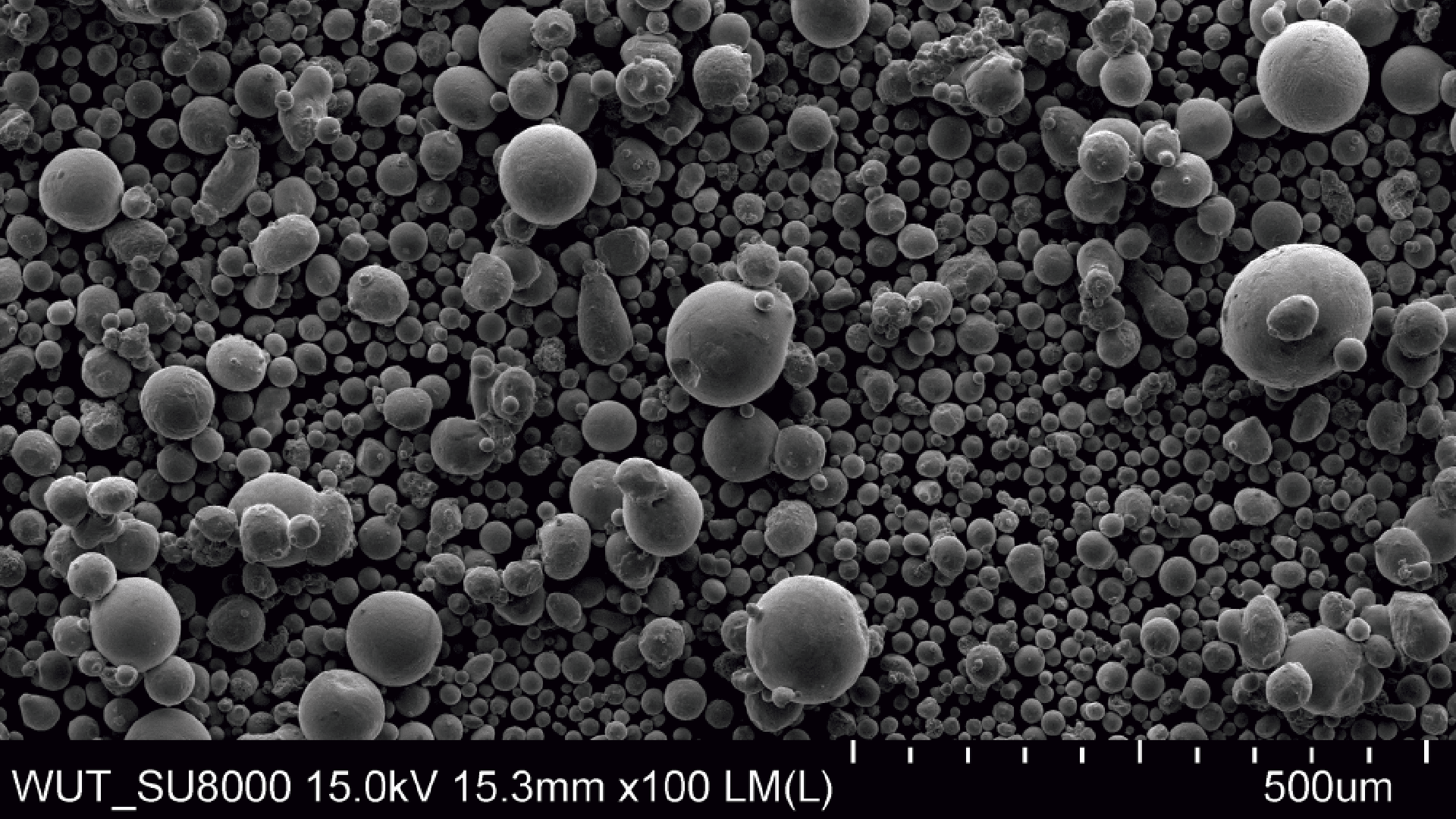

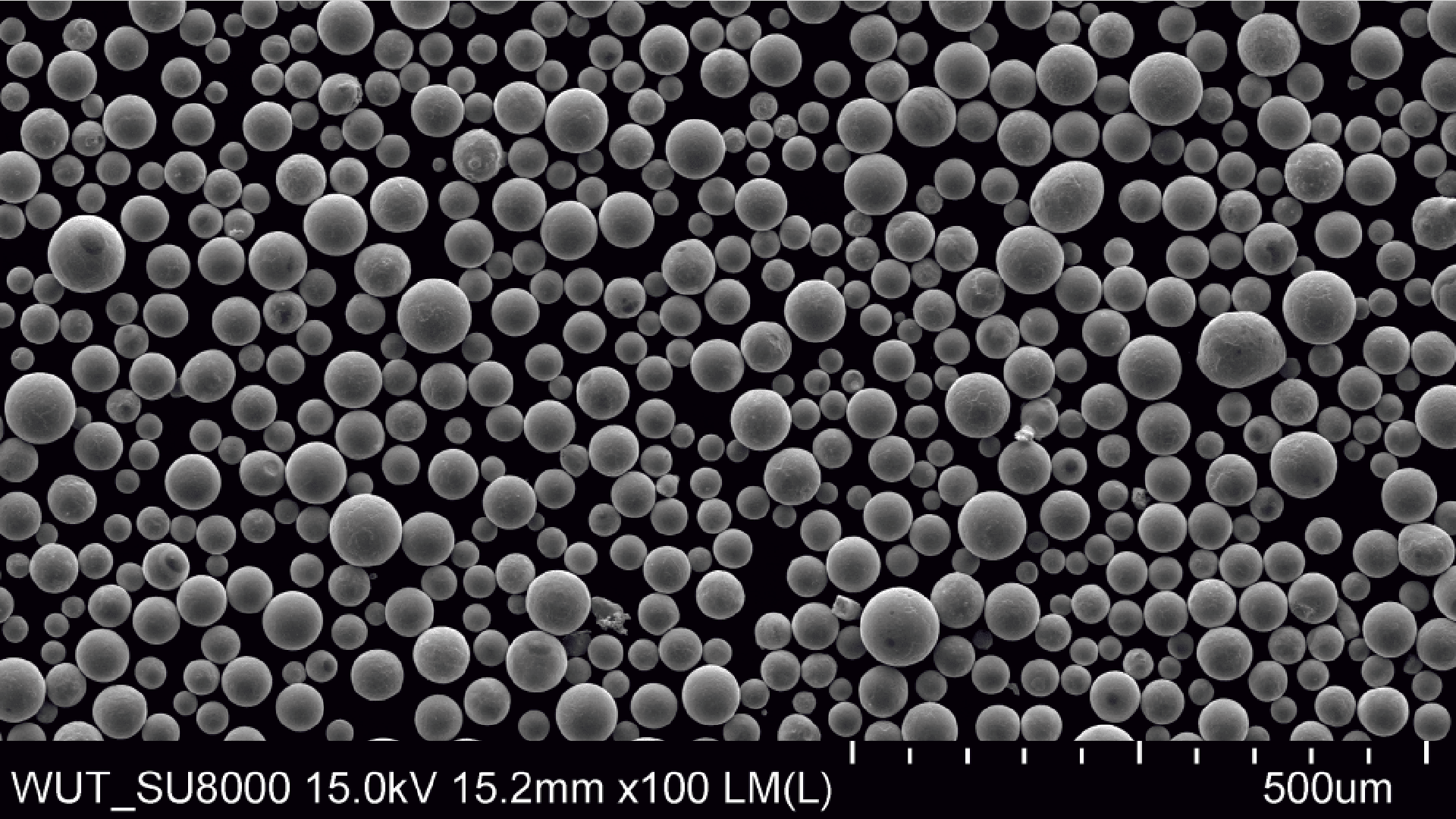

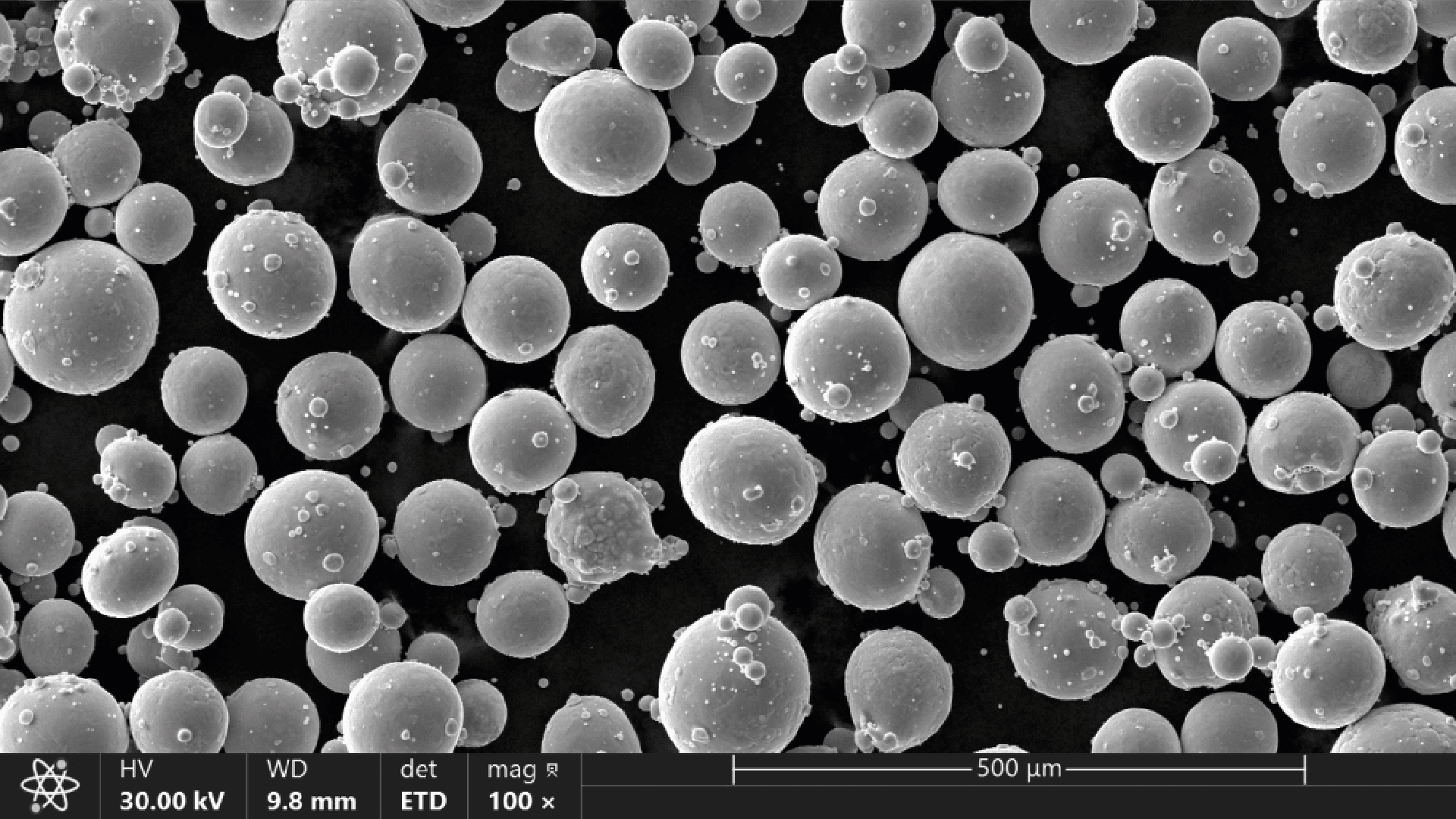

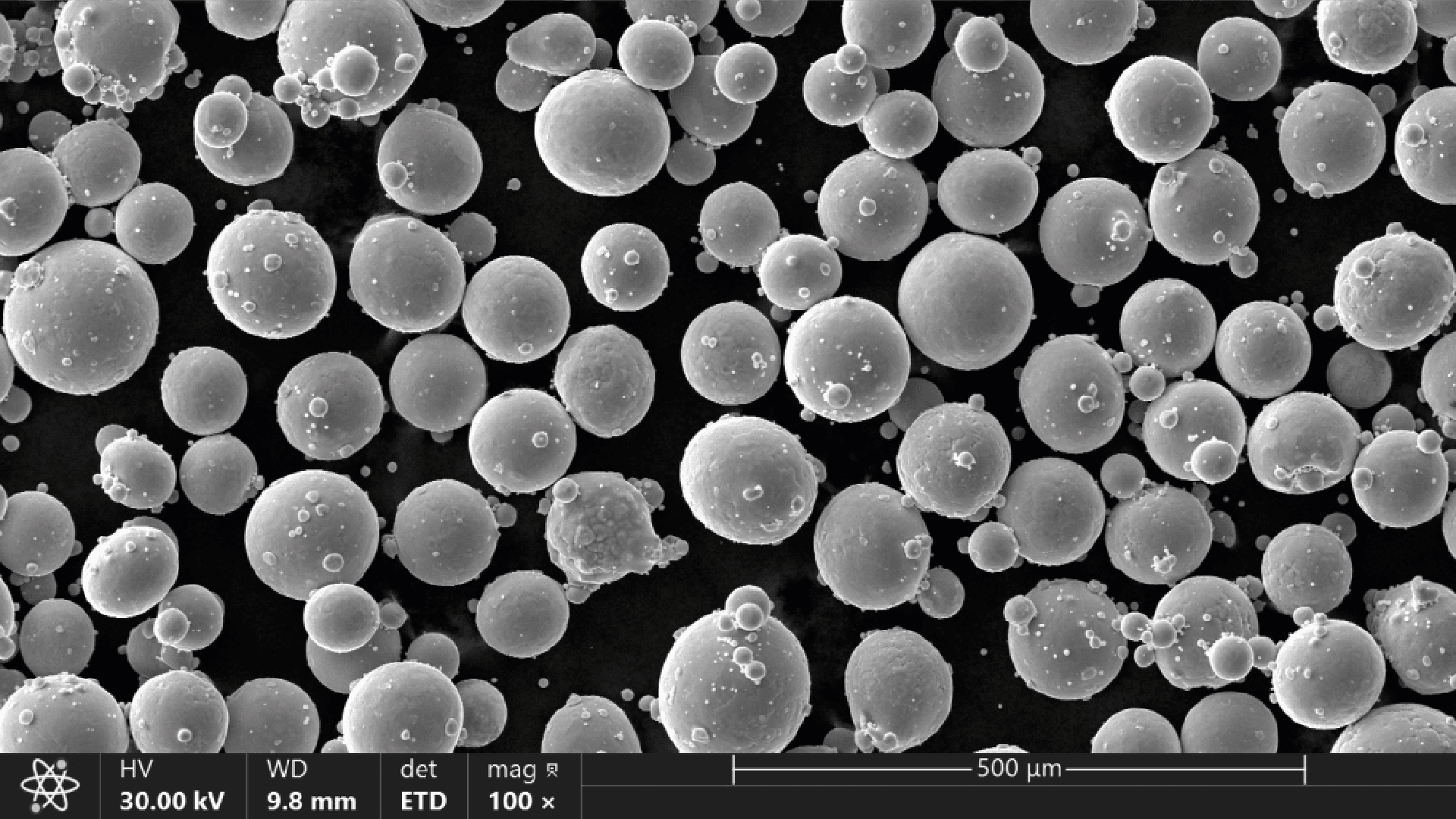

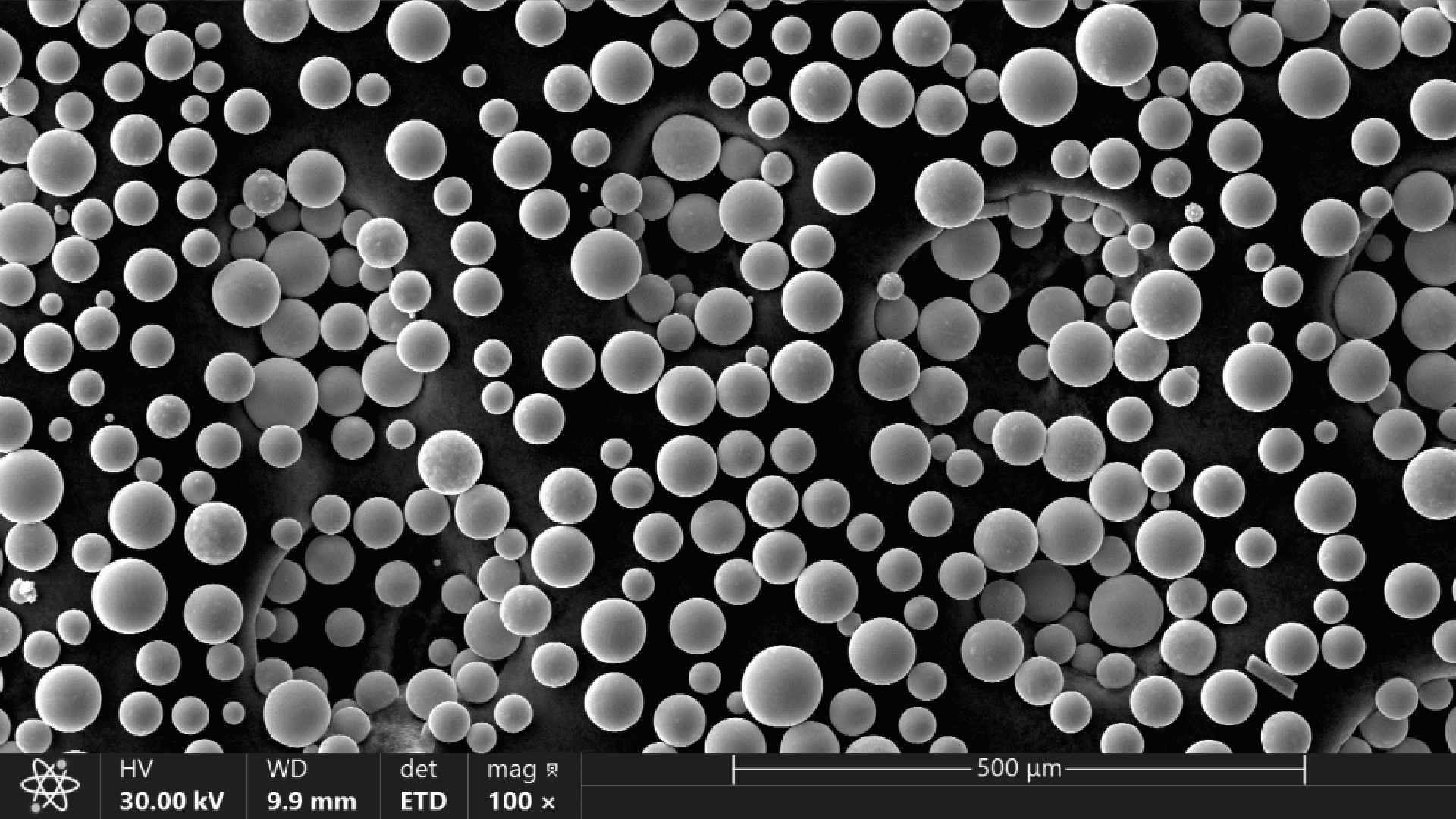

SEM

IMAGES

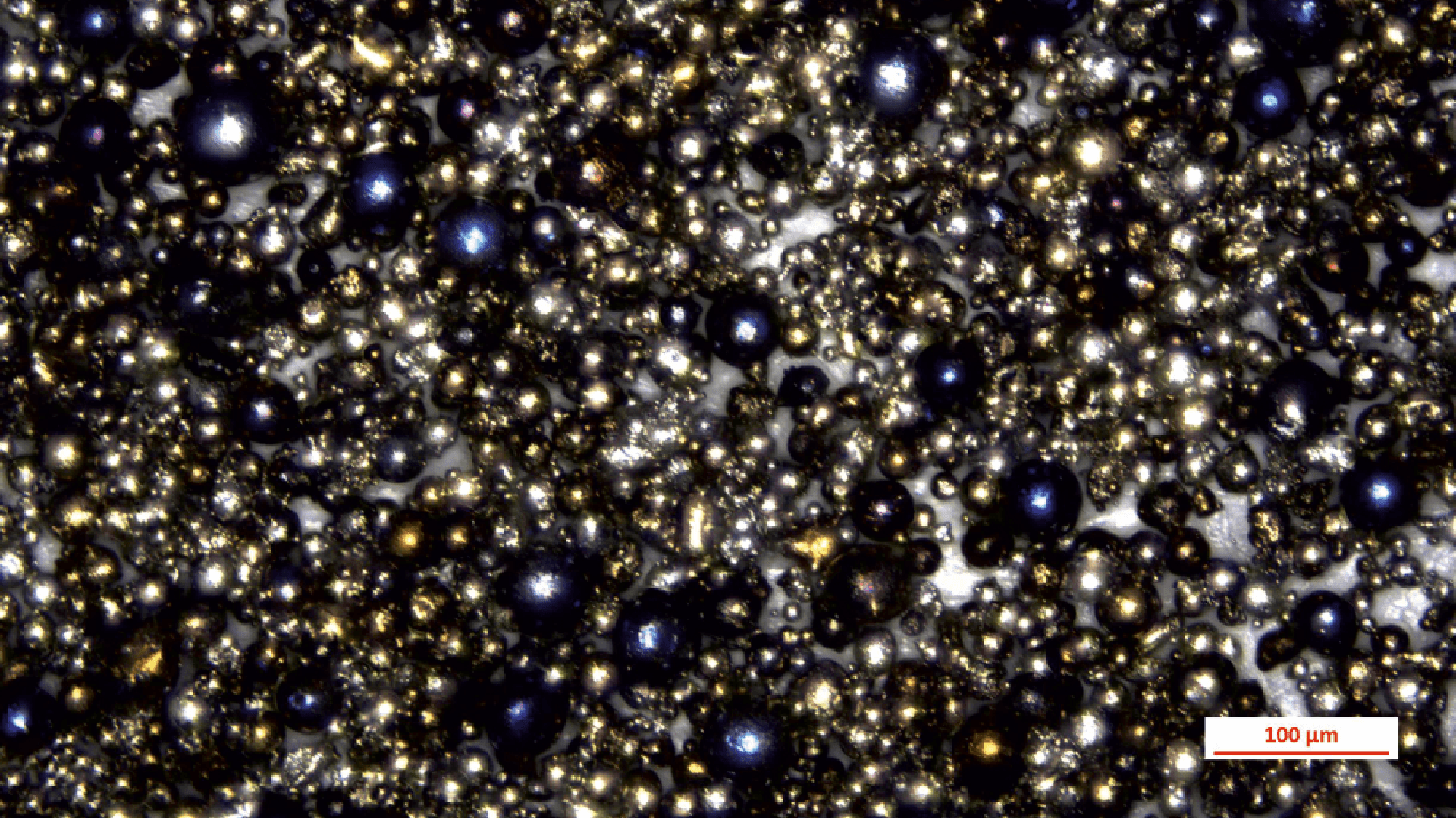

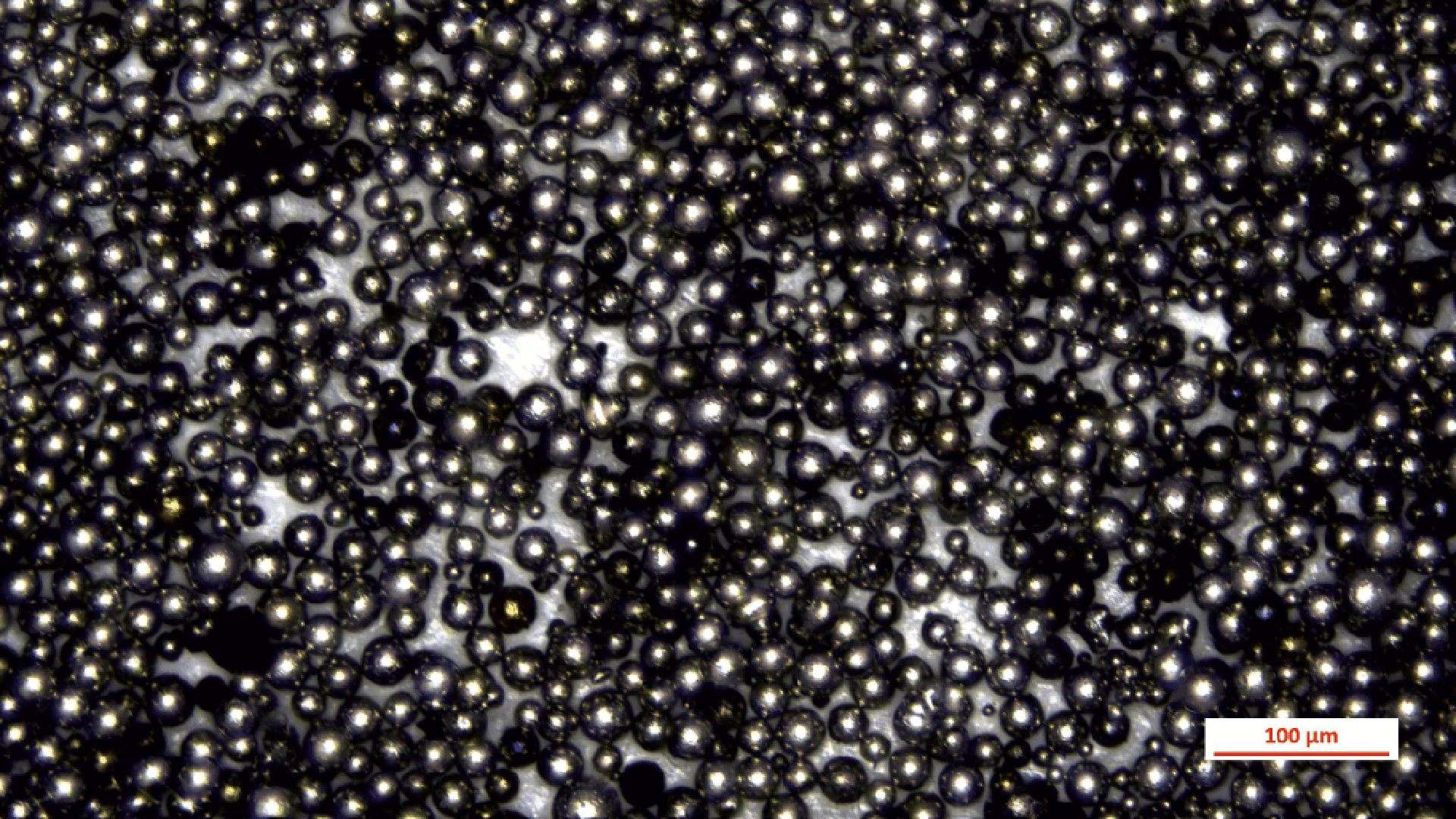

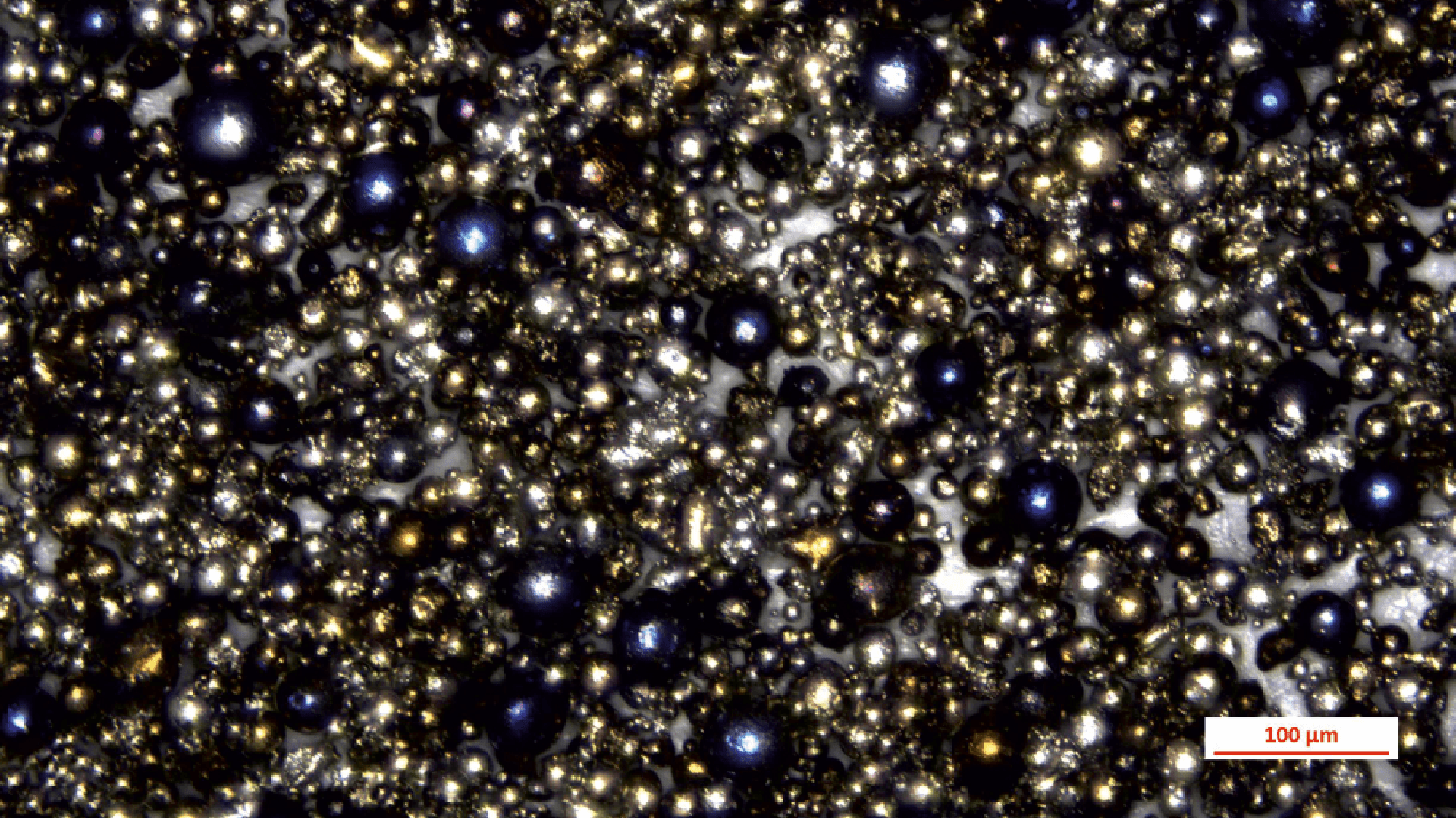

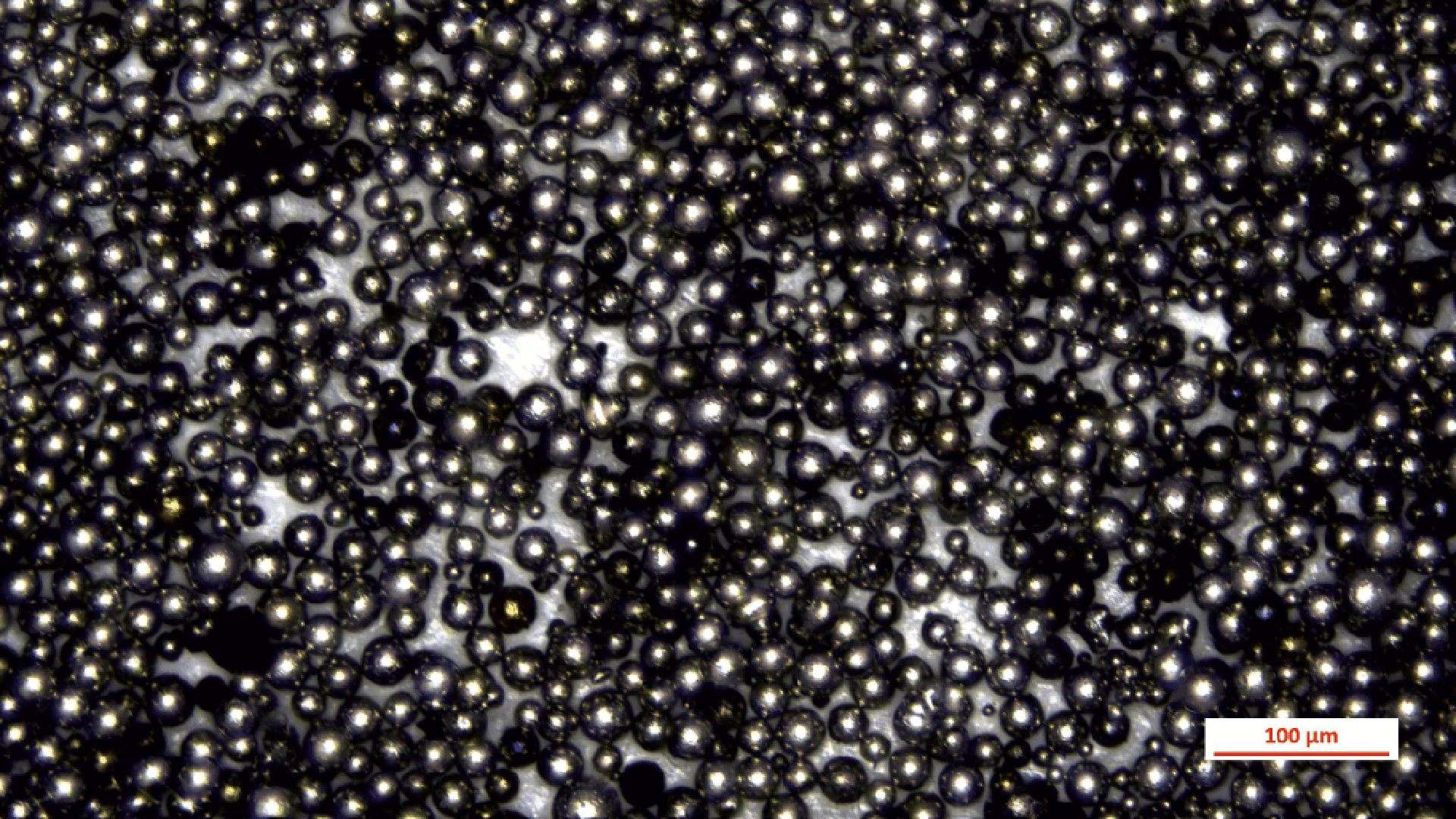

LIGHT MICROSCOPE

IMAGES

MATERIAL

MS1

Is your metal

powder out of spec?

SEM

IMAGES

LIGHT MICROSCOPE

IMAGES

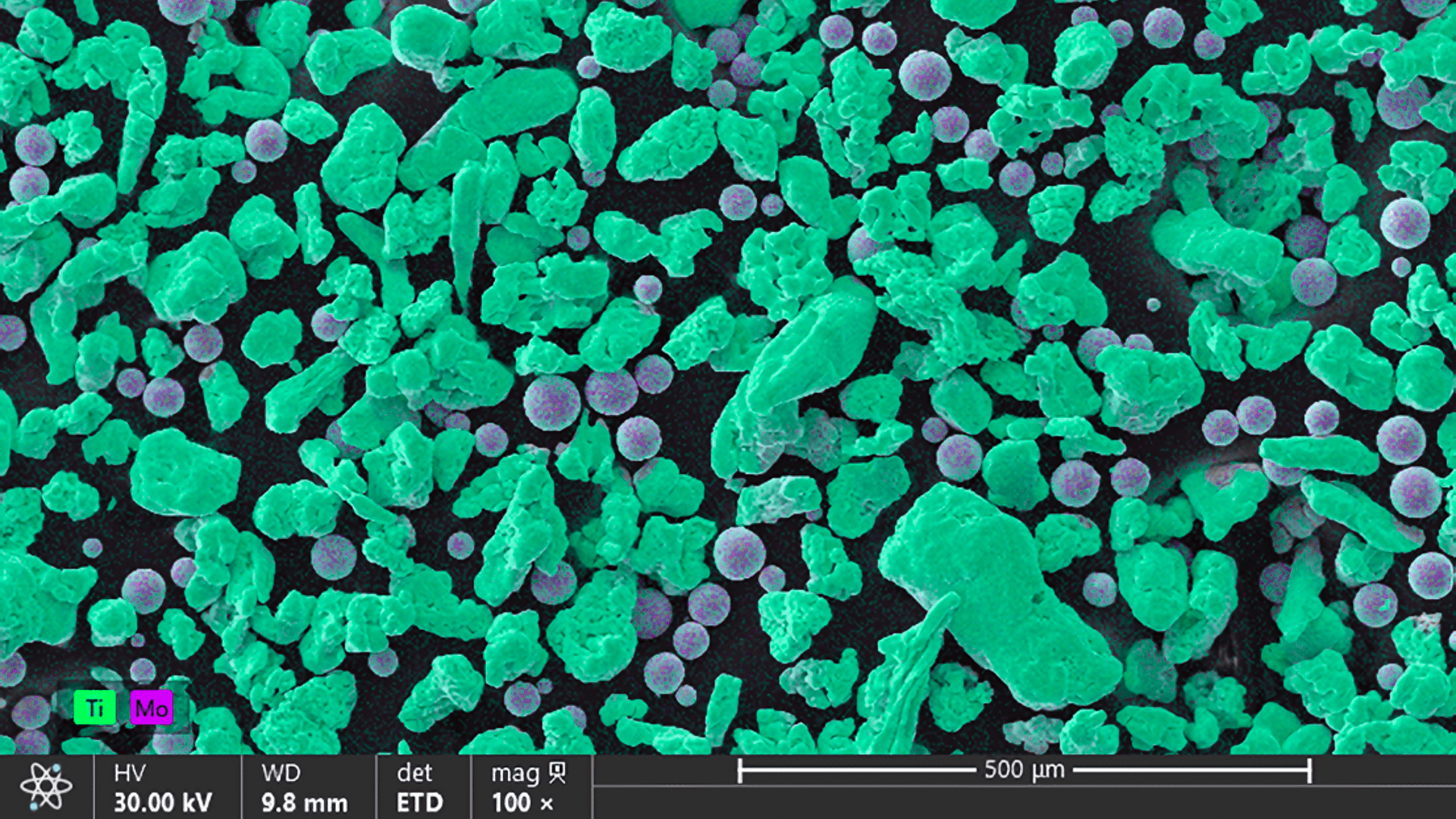

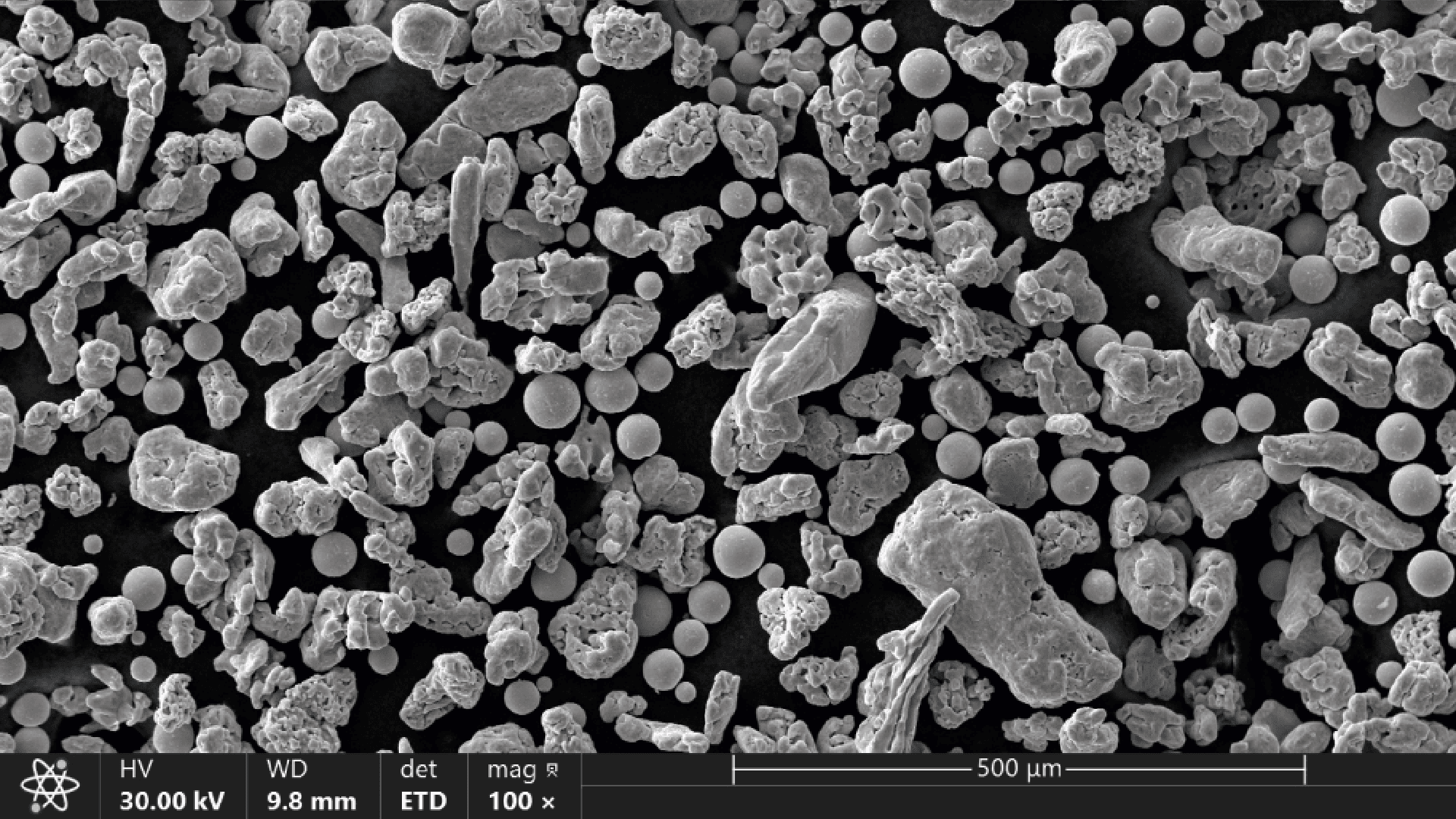

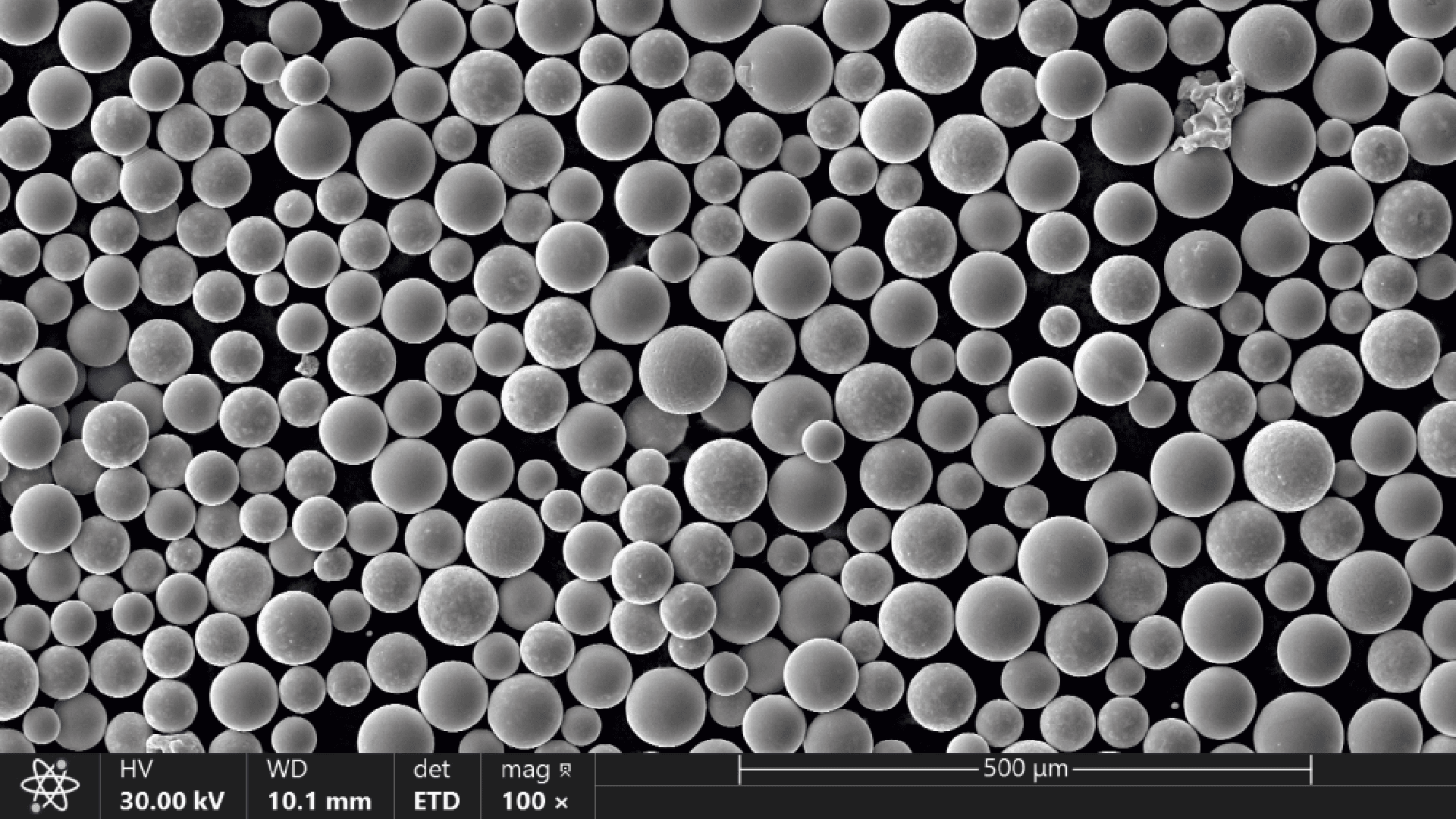

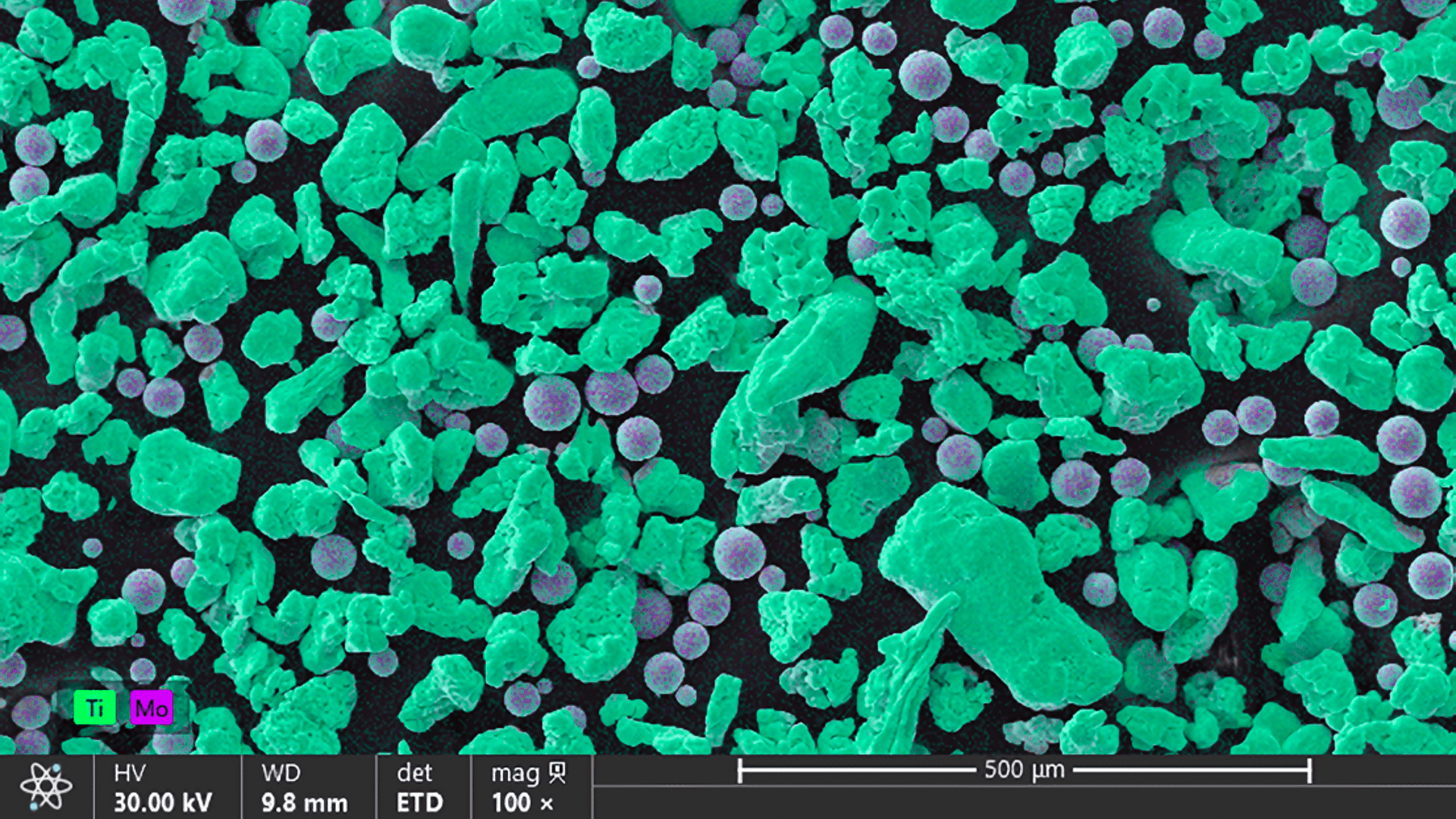

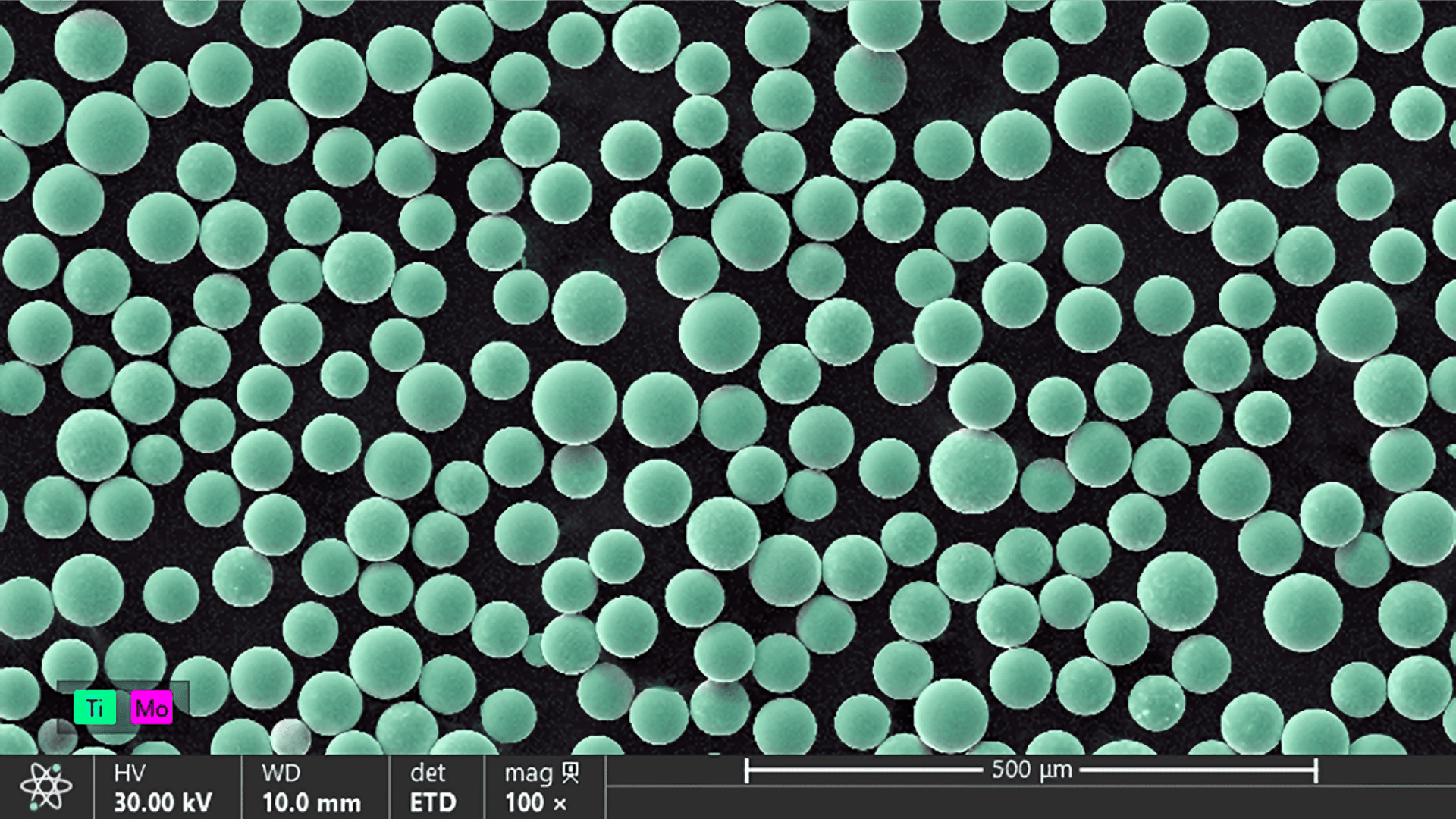

MATERIAL

TiMo

Have you tried

in-situ alloying in AM?

SEM

IMAGES

EDS

COMPOSITIONAL MAPS

MATERIAL

TiMo

Have you tried

in-situ alloying in AM?

SEM

IMAGES

EDS

COMPOSITIONAL MAPS

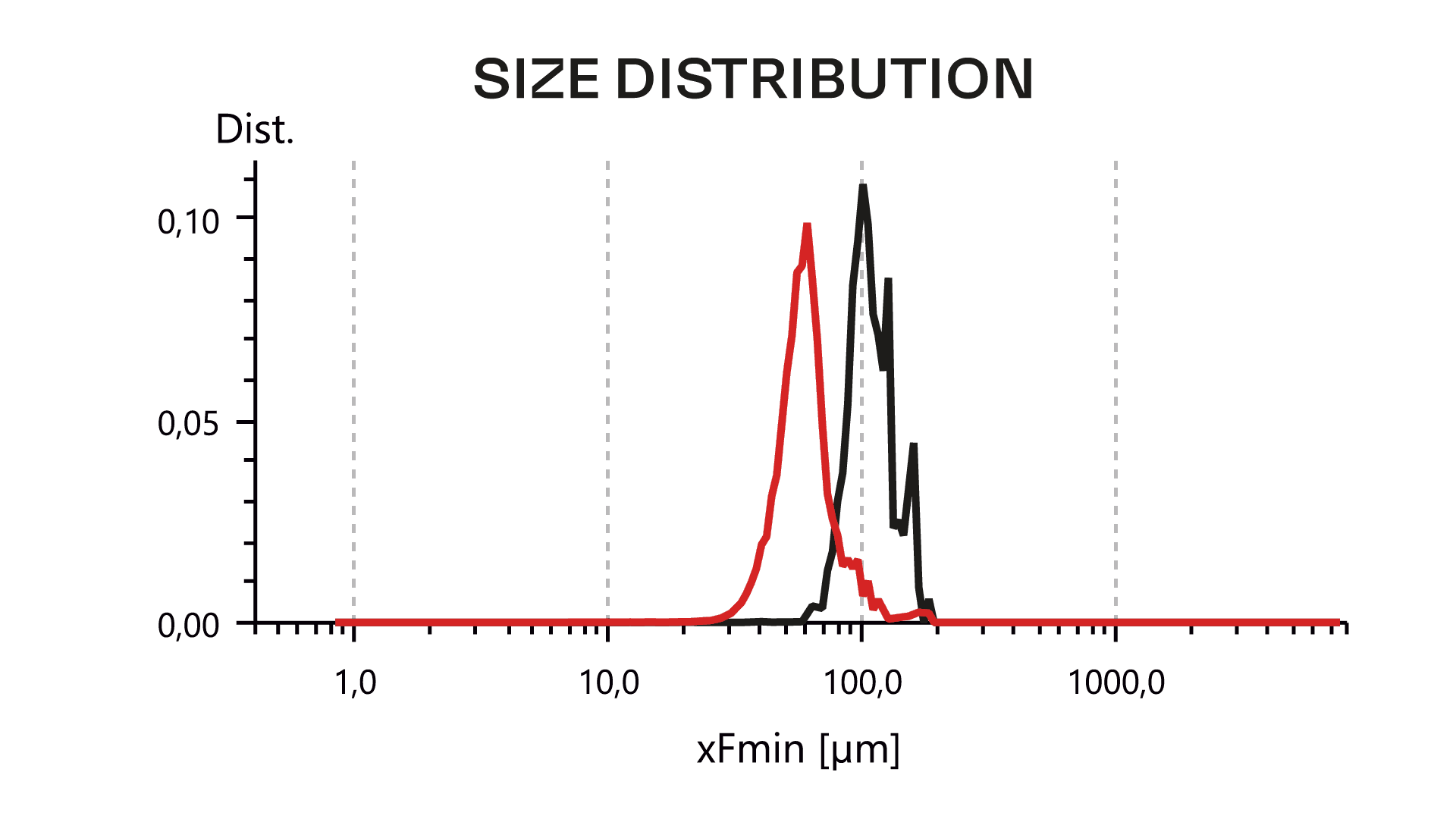

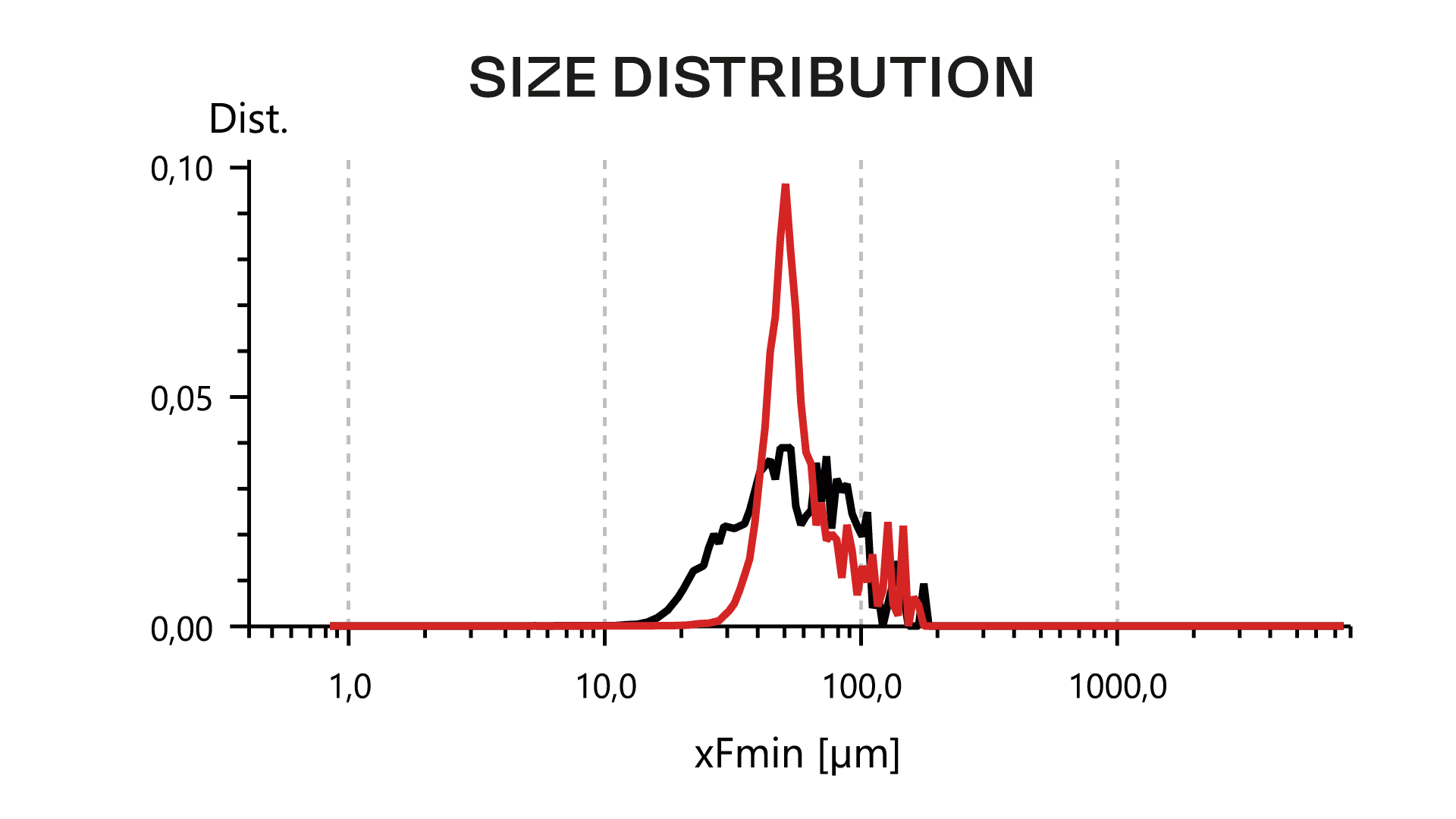

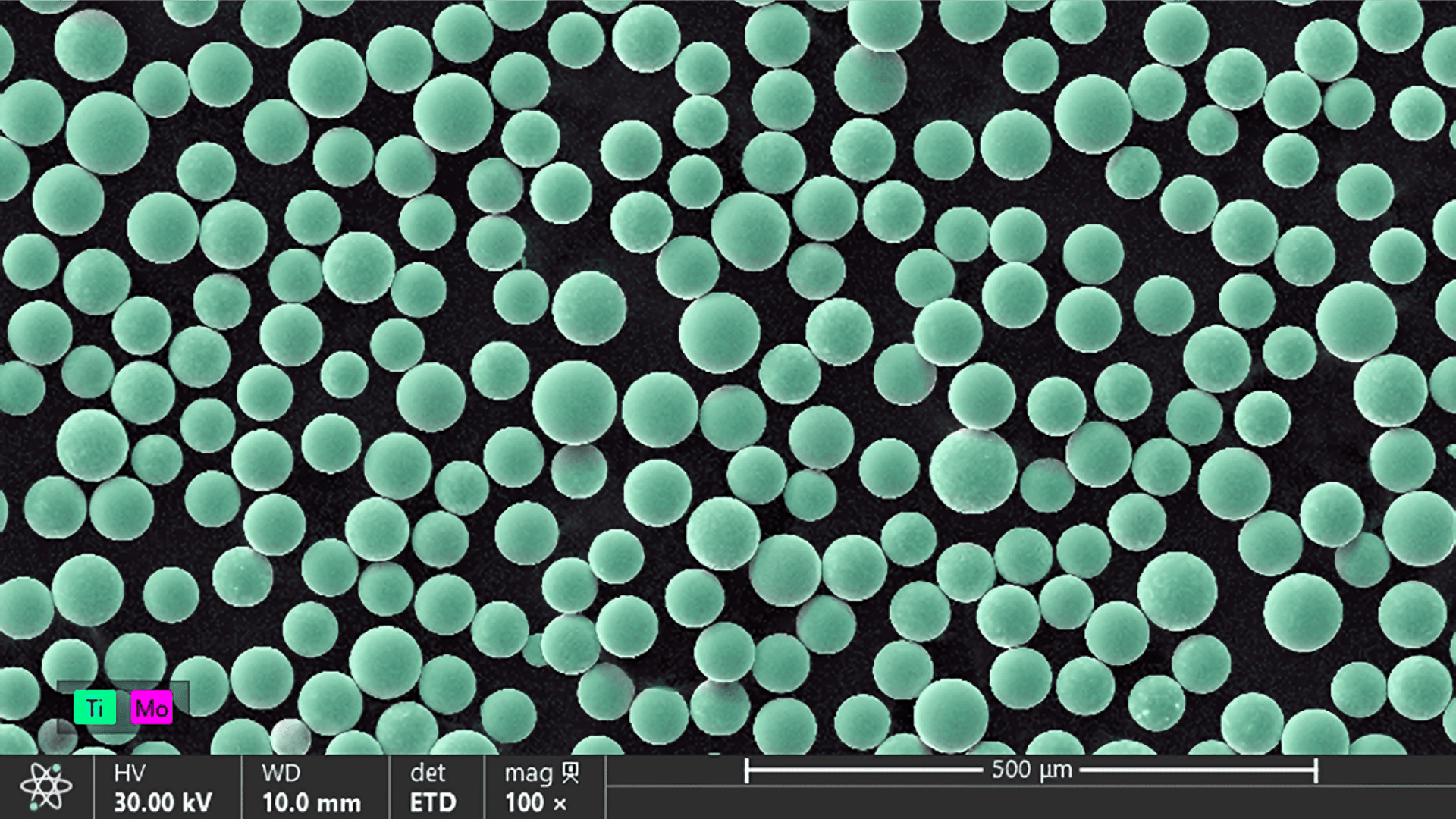

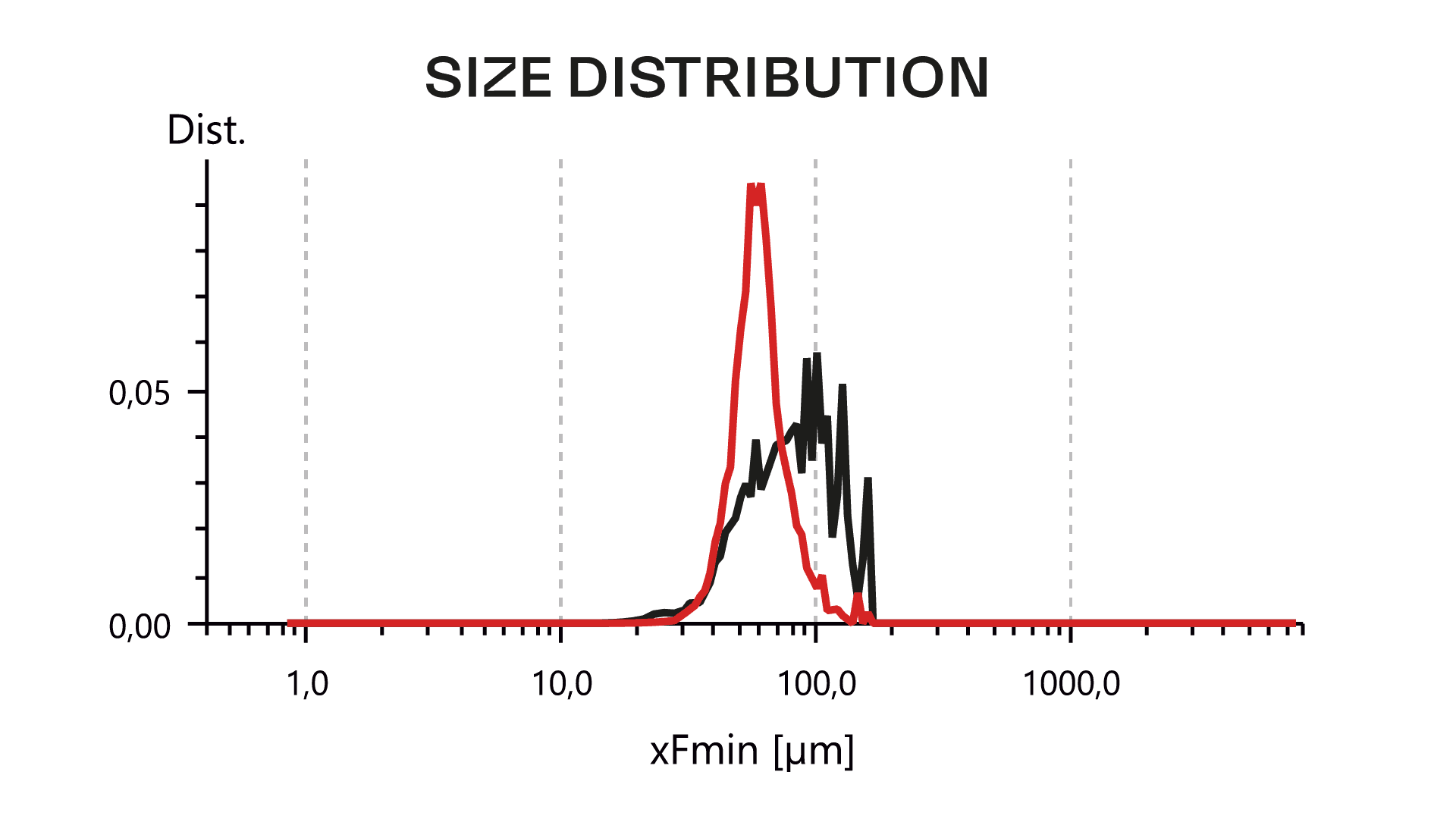

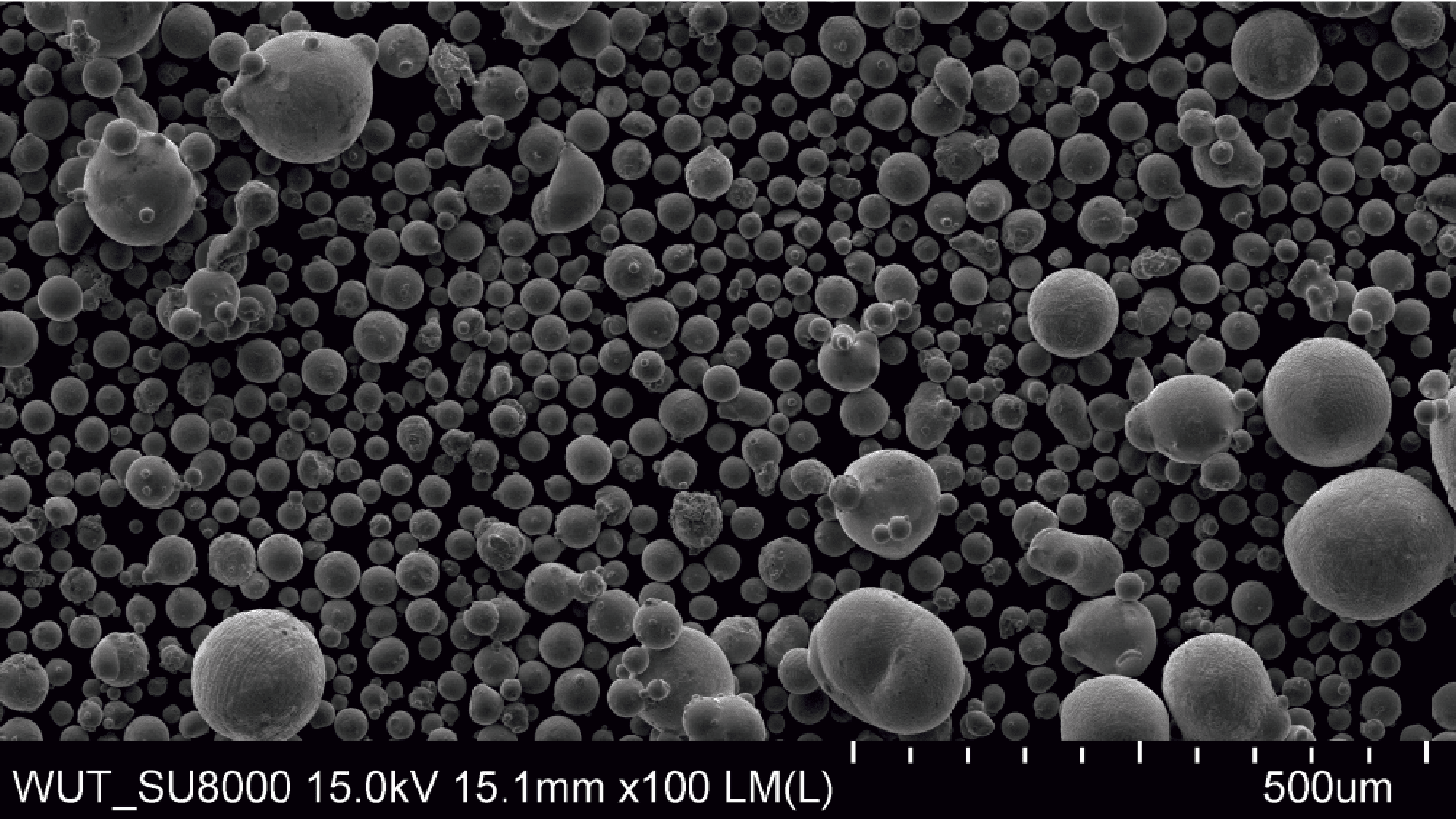

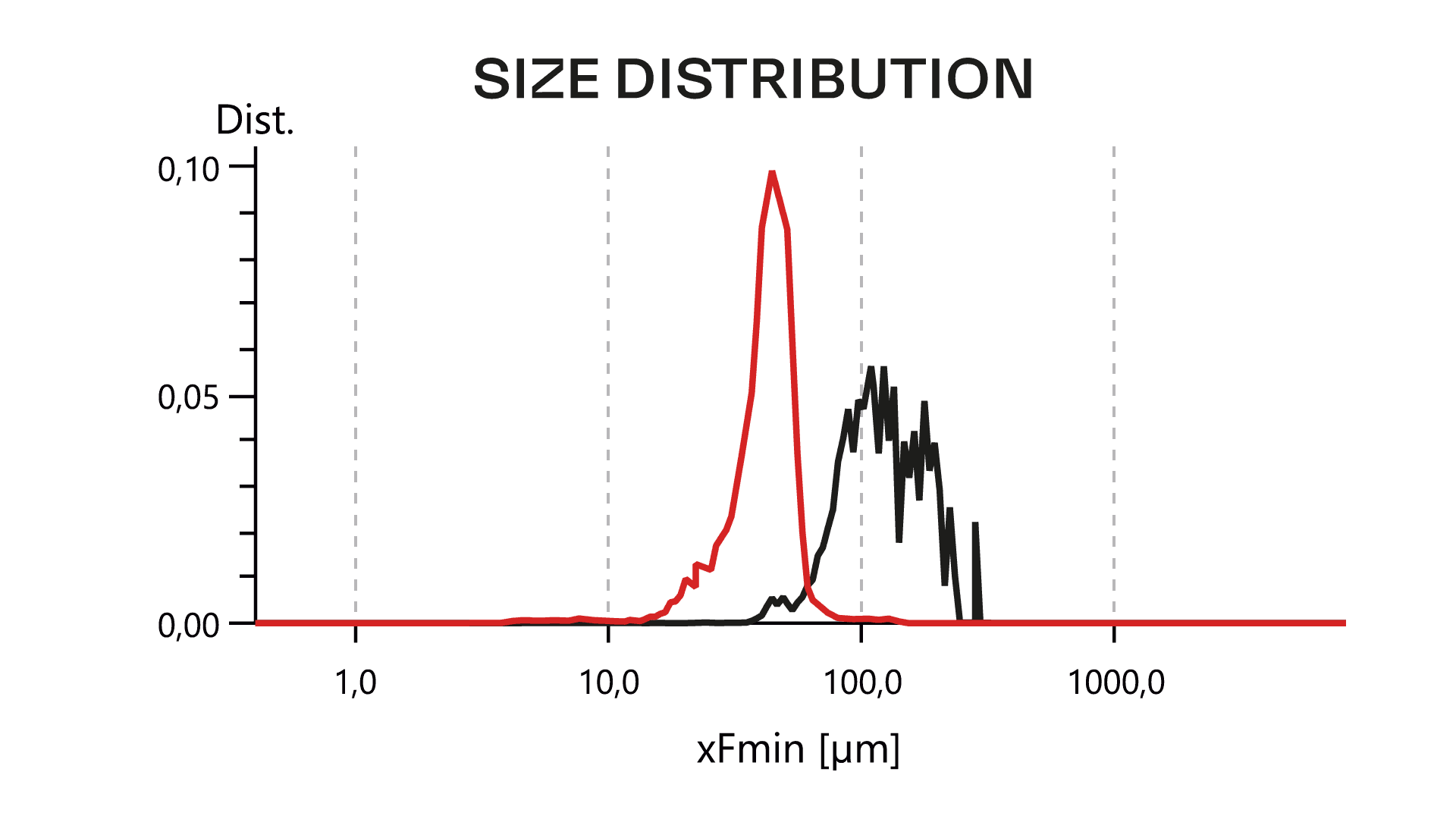

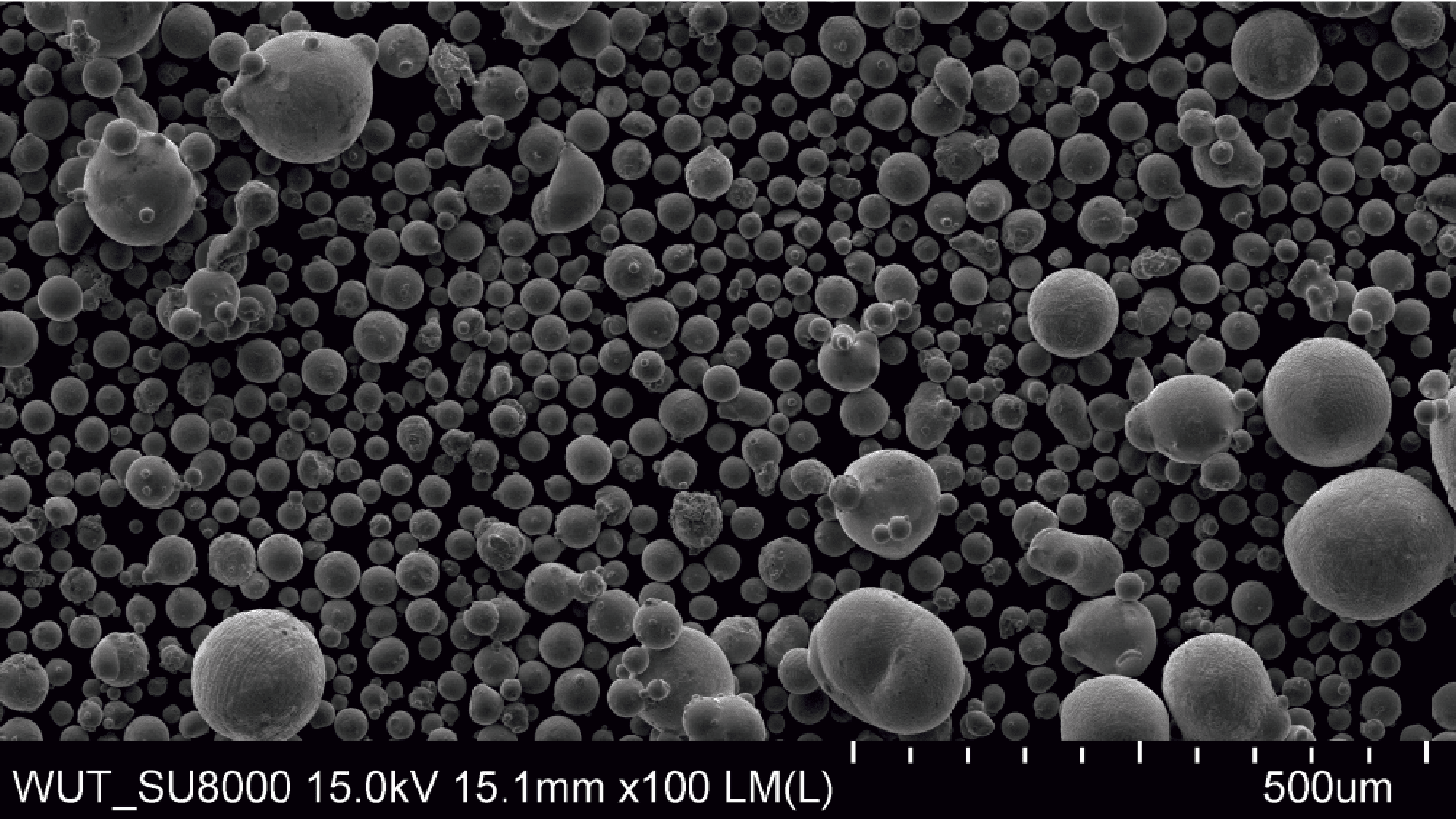

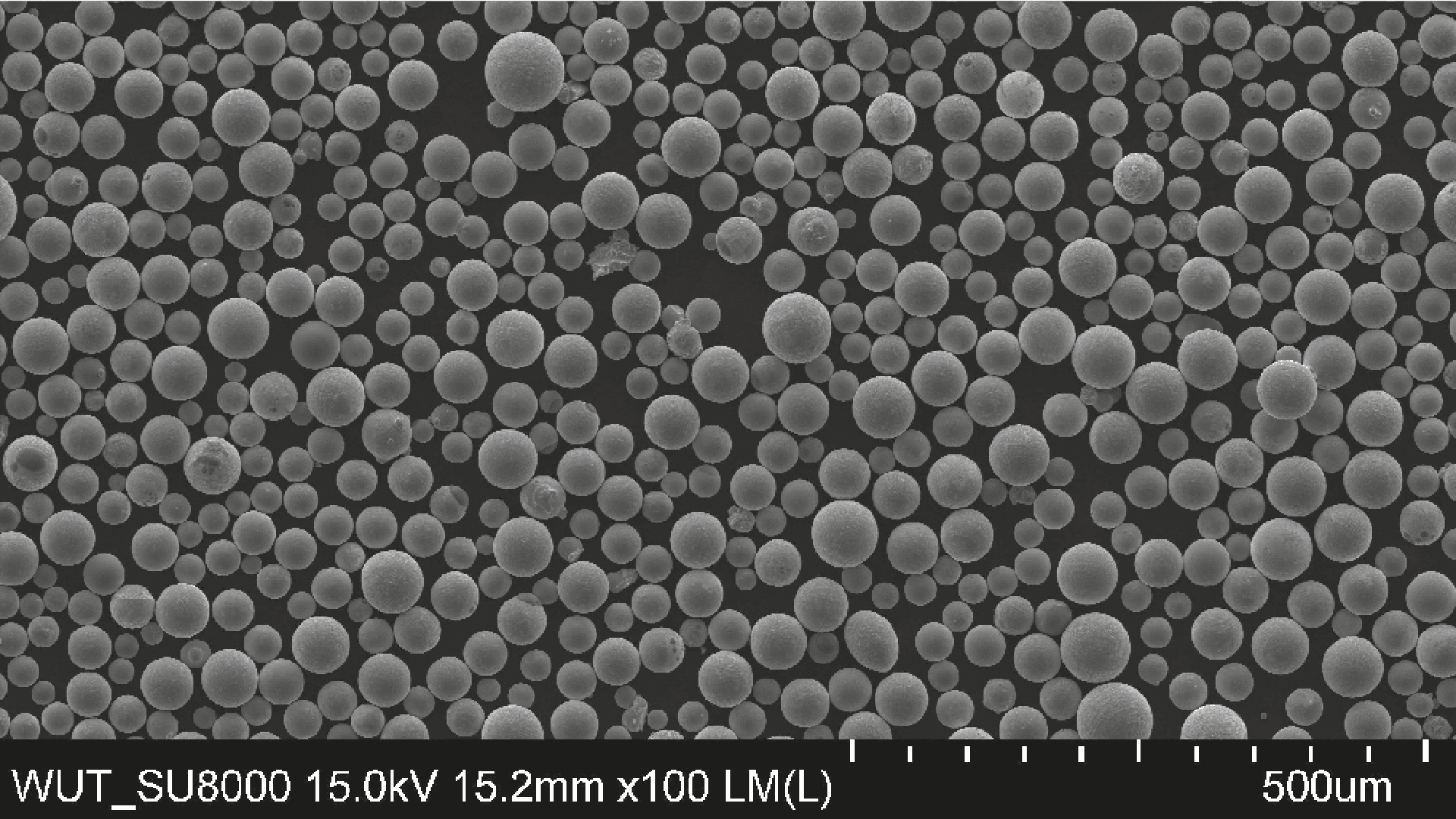

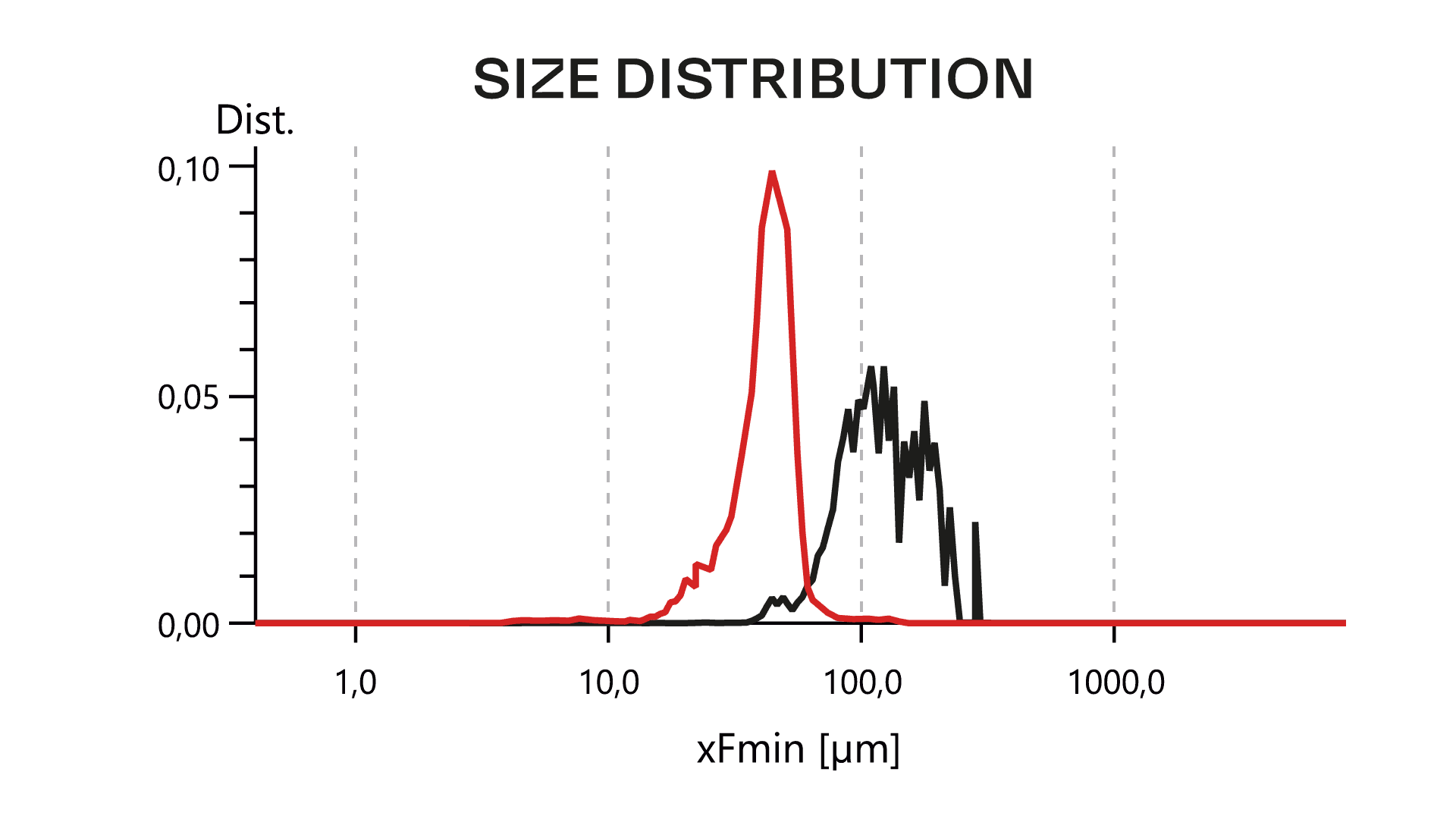

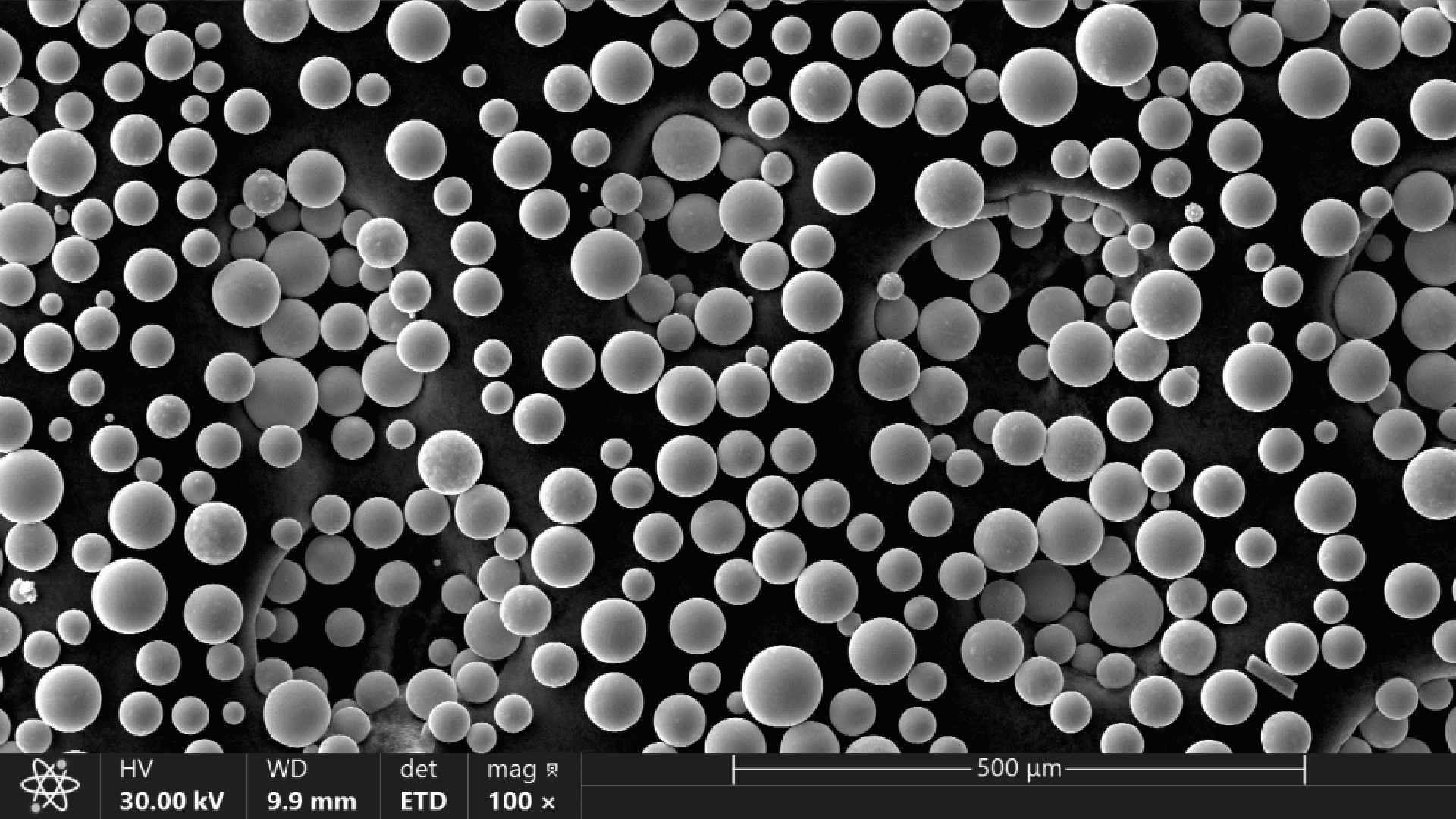

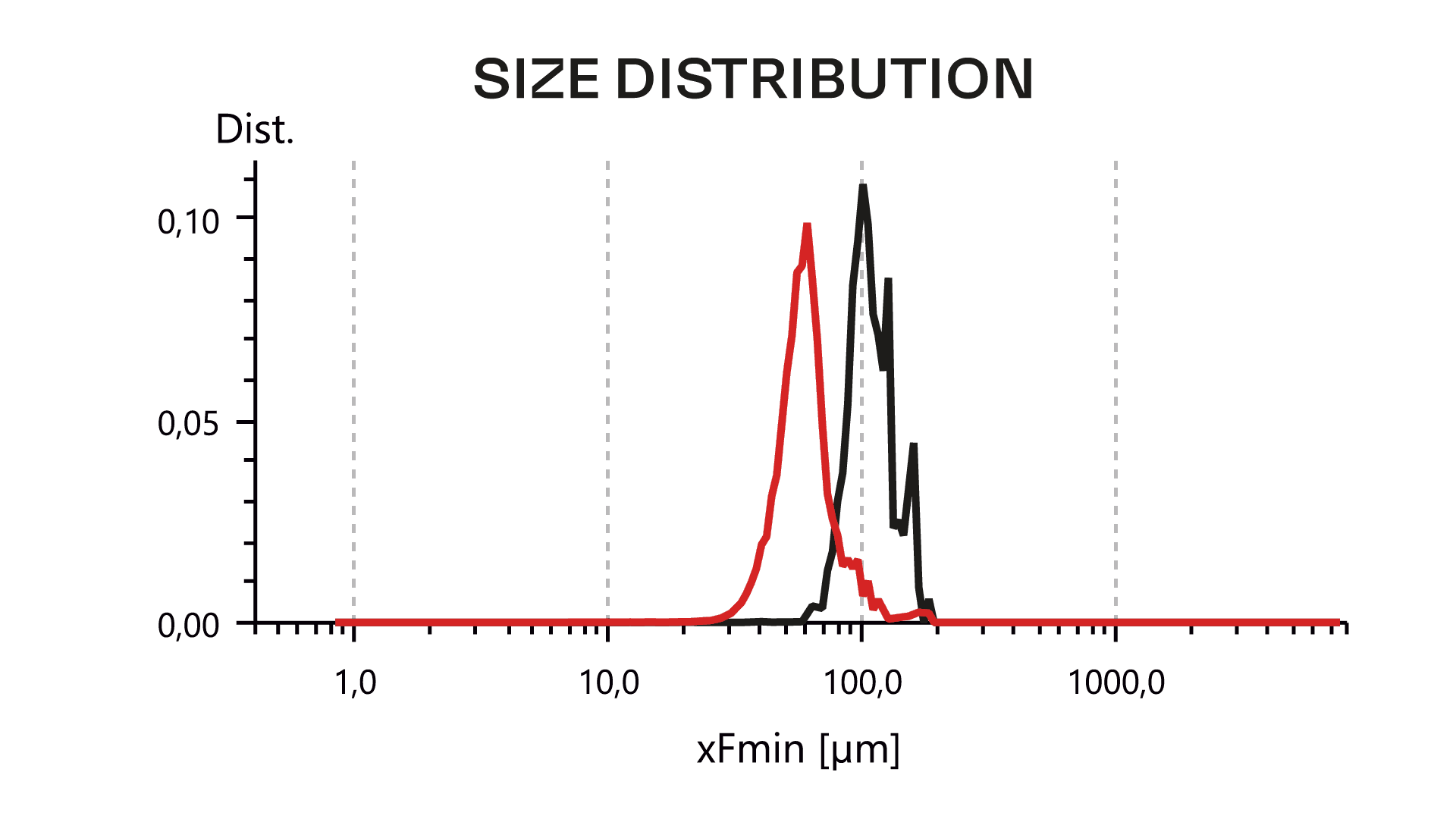

MATERIAL

INCONEL

Out-of-size powders

holding you back?

SEM

IMAGES

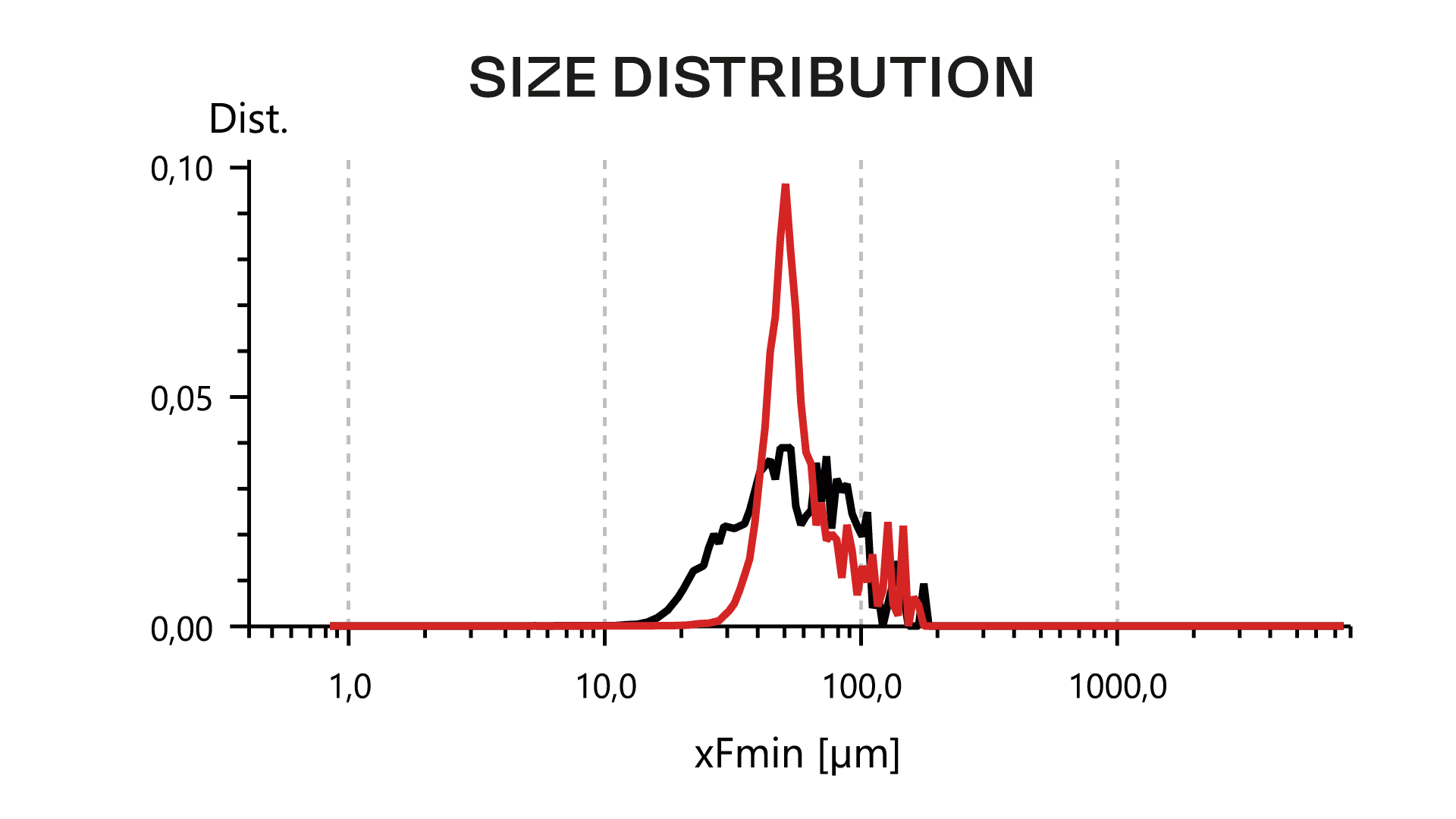

Particle Size

Distribution

MATERIAL

INCONEL

Out-of-size powders

holding you back?

SEM

IMAGES

Particle Size

Distribution

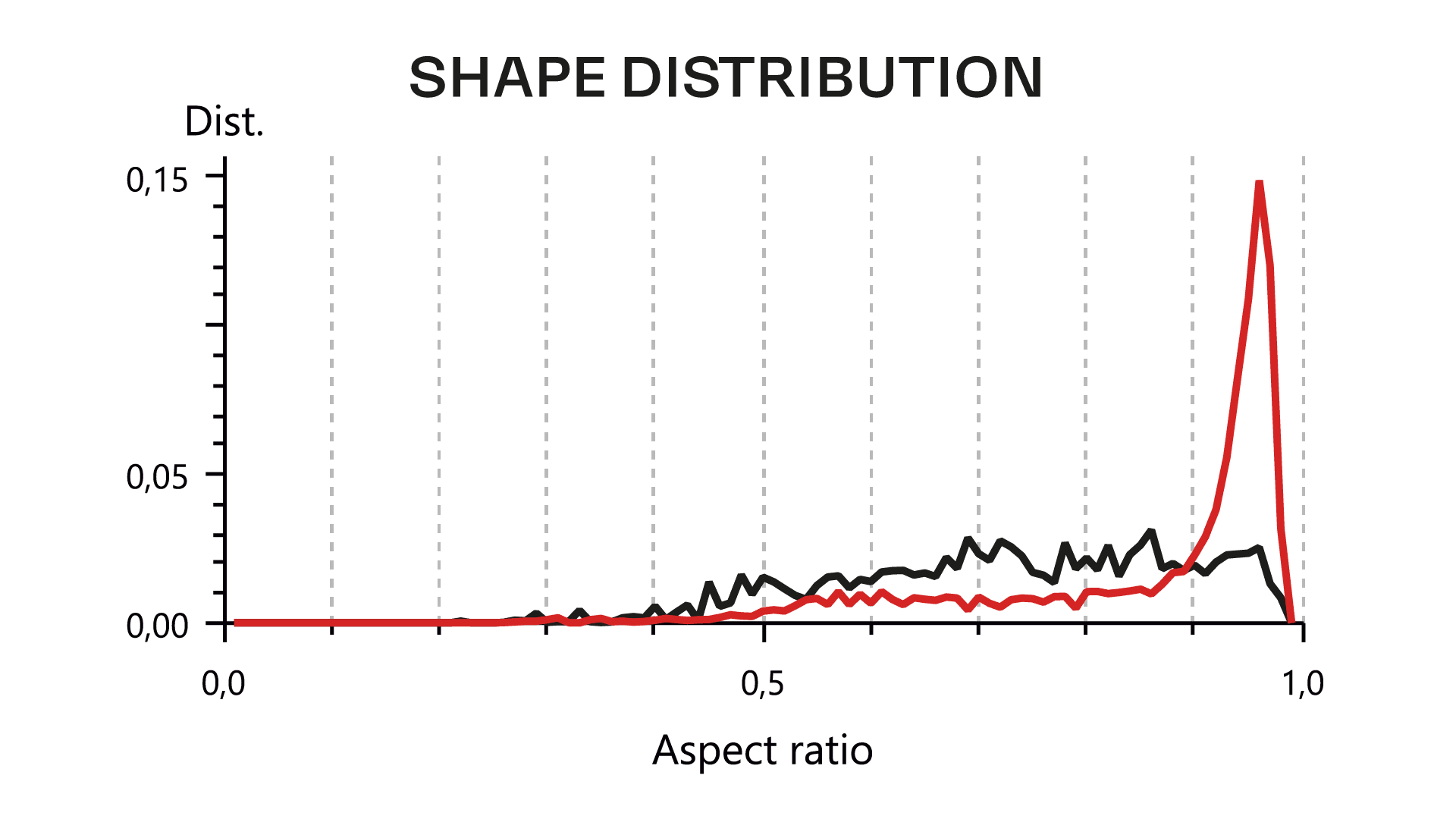

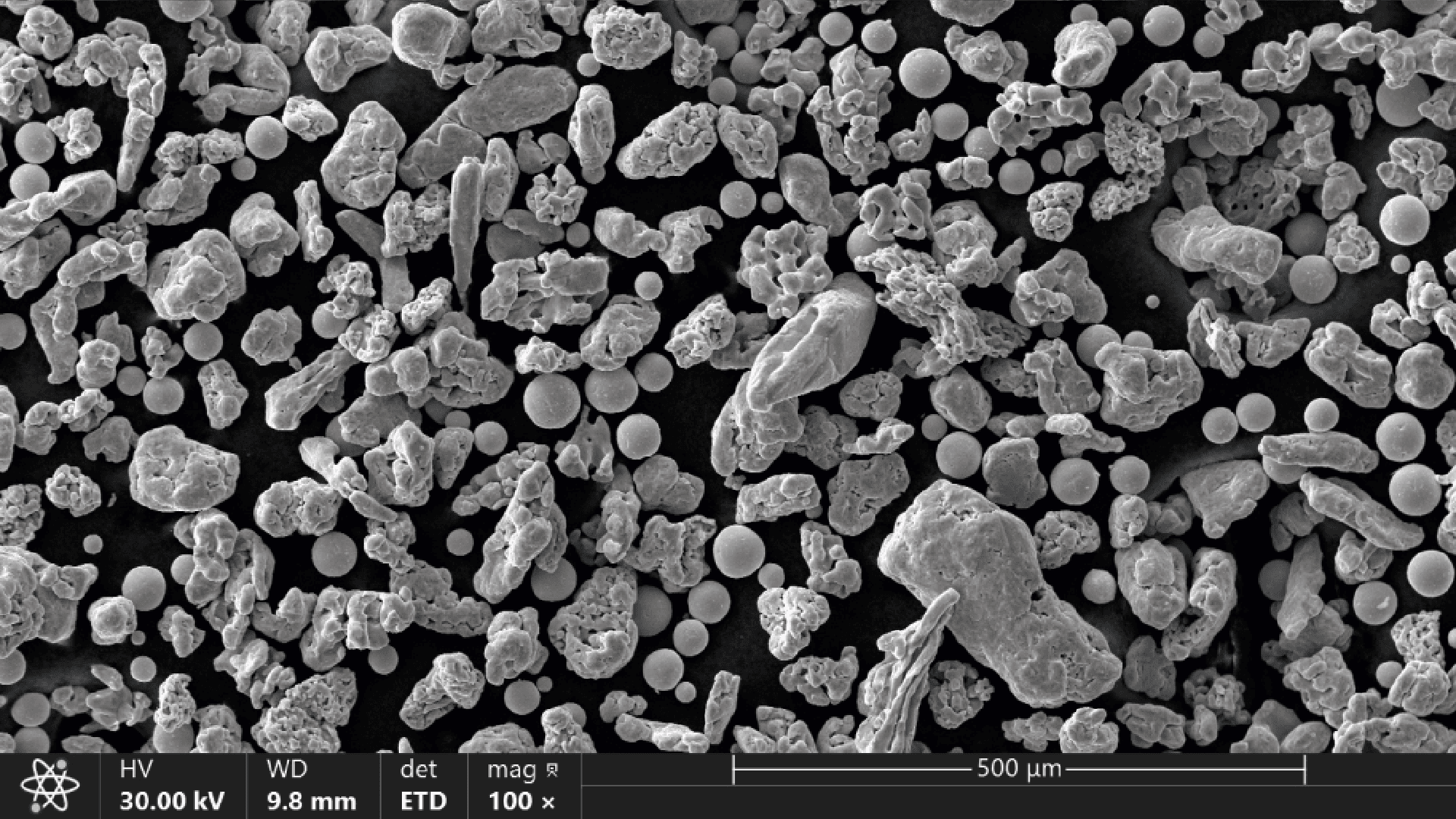

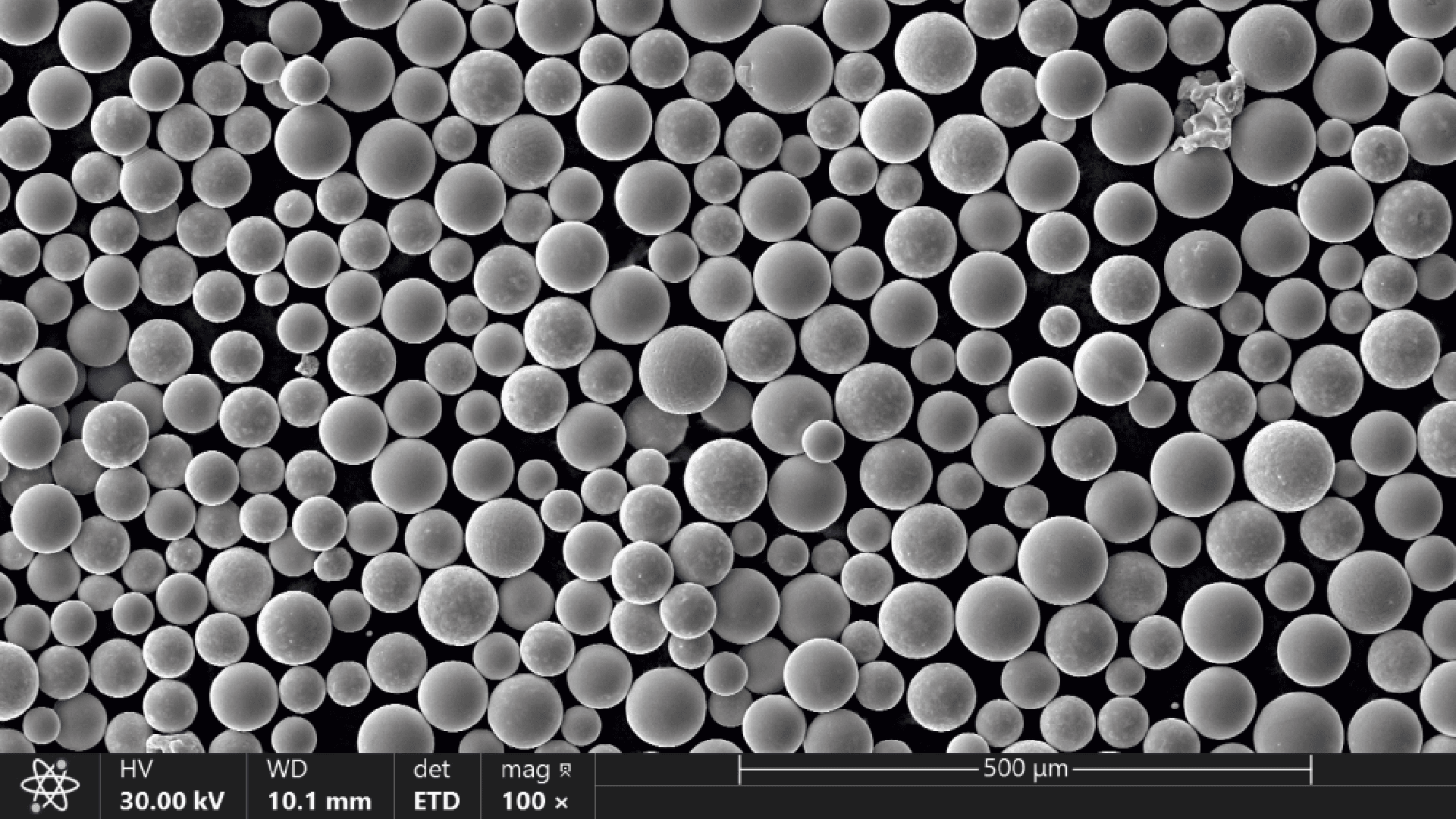

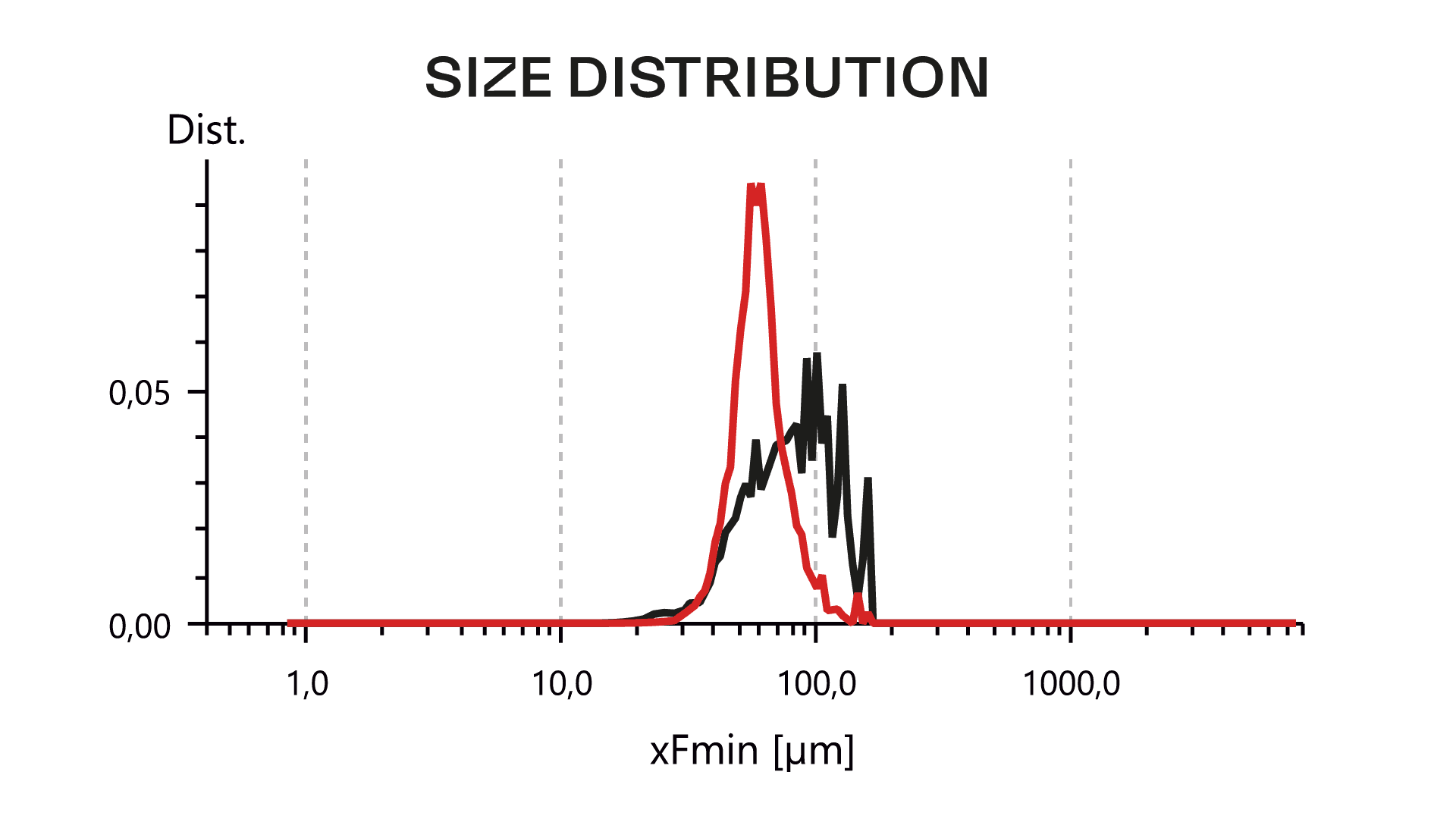

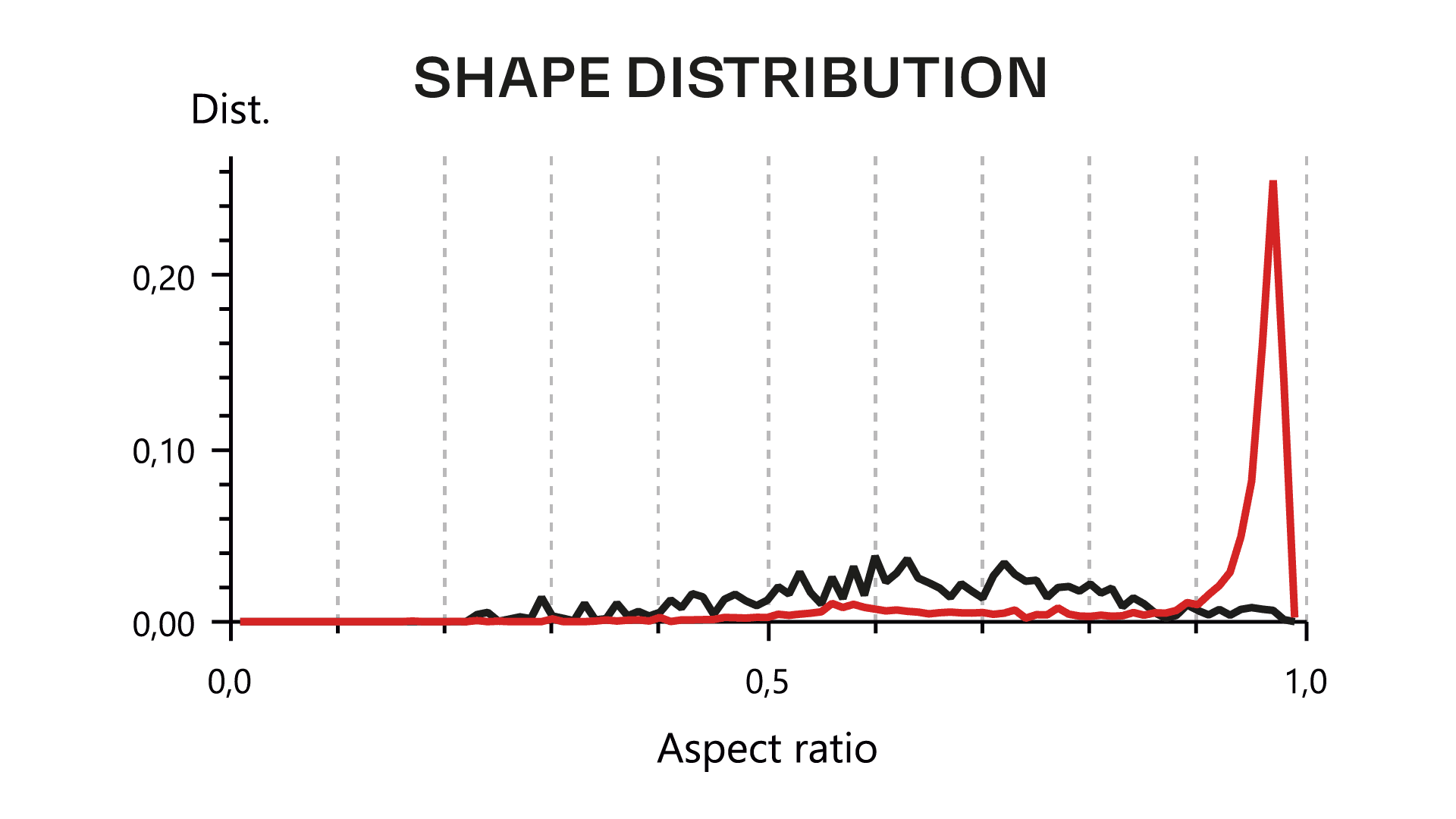

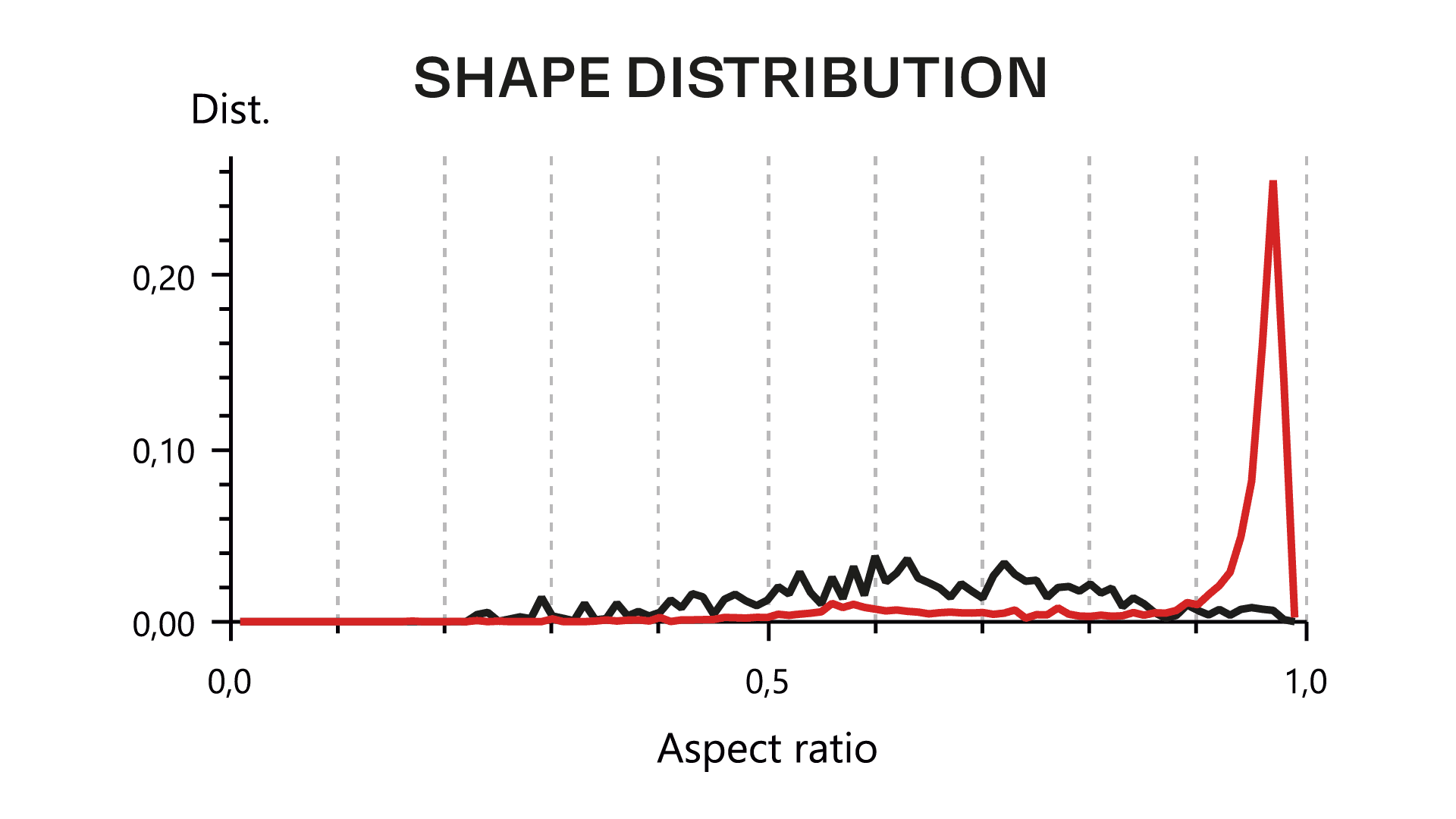

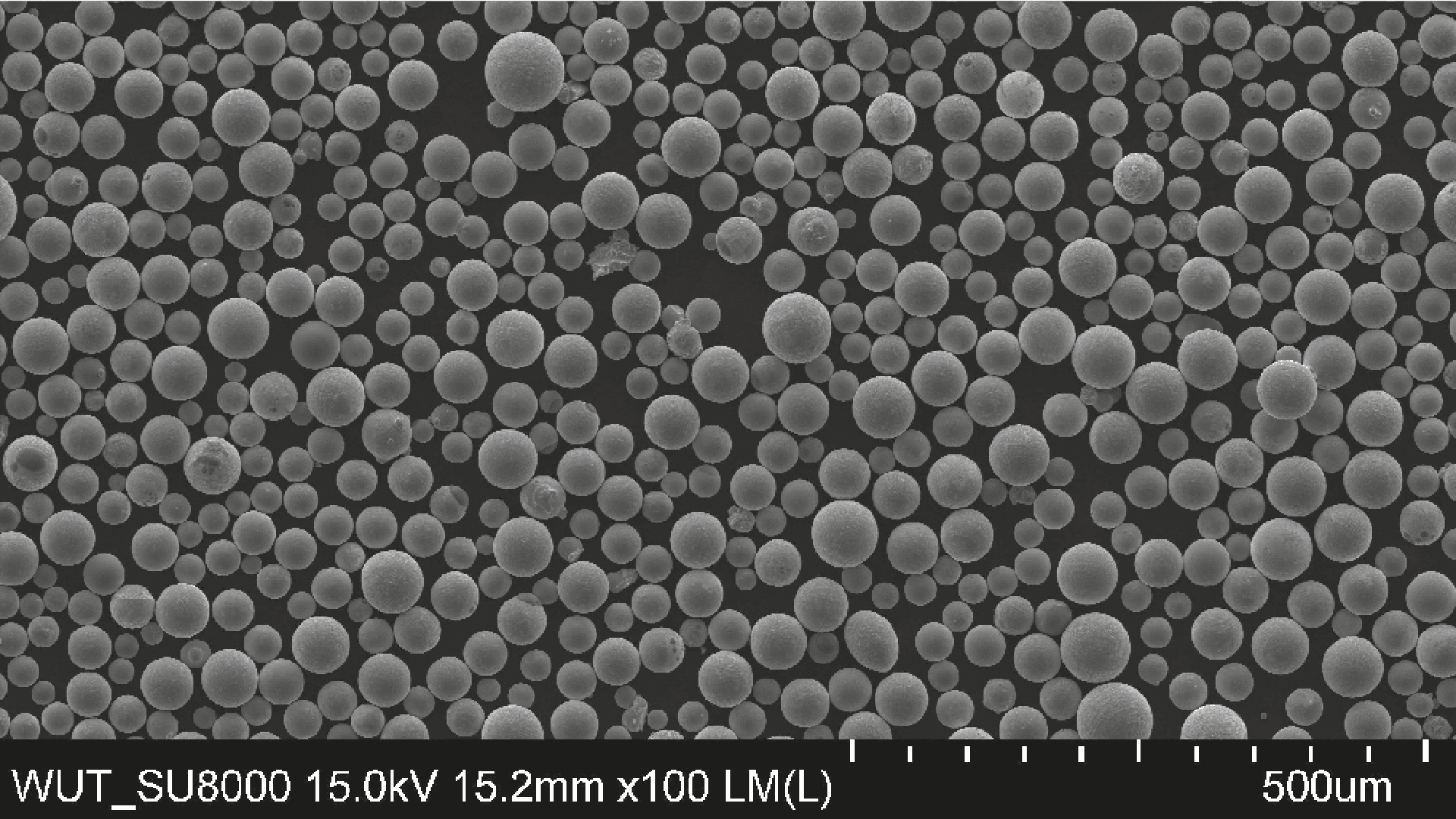

MATERIAL

Ti64

Limited to printing

with non-spherical powders?

SEM

IMAGES

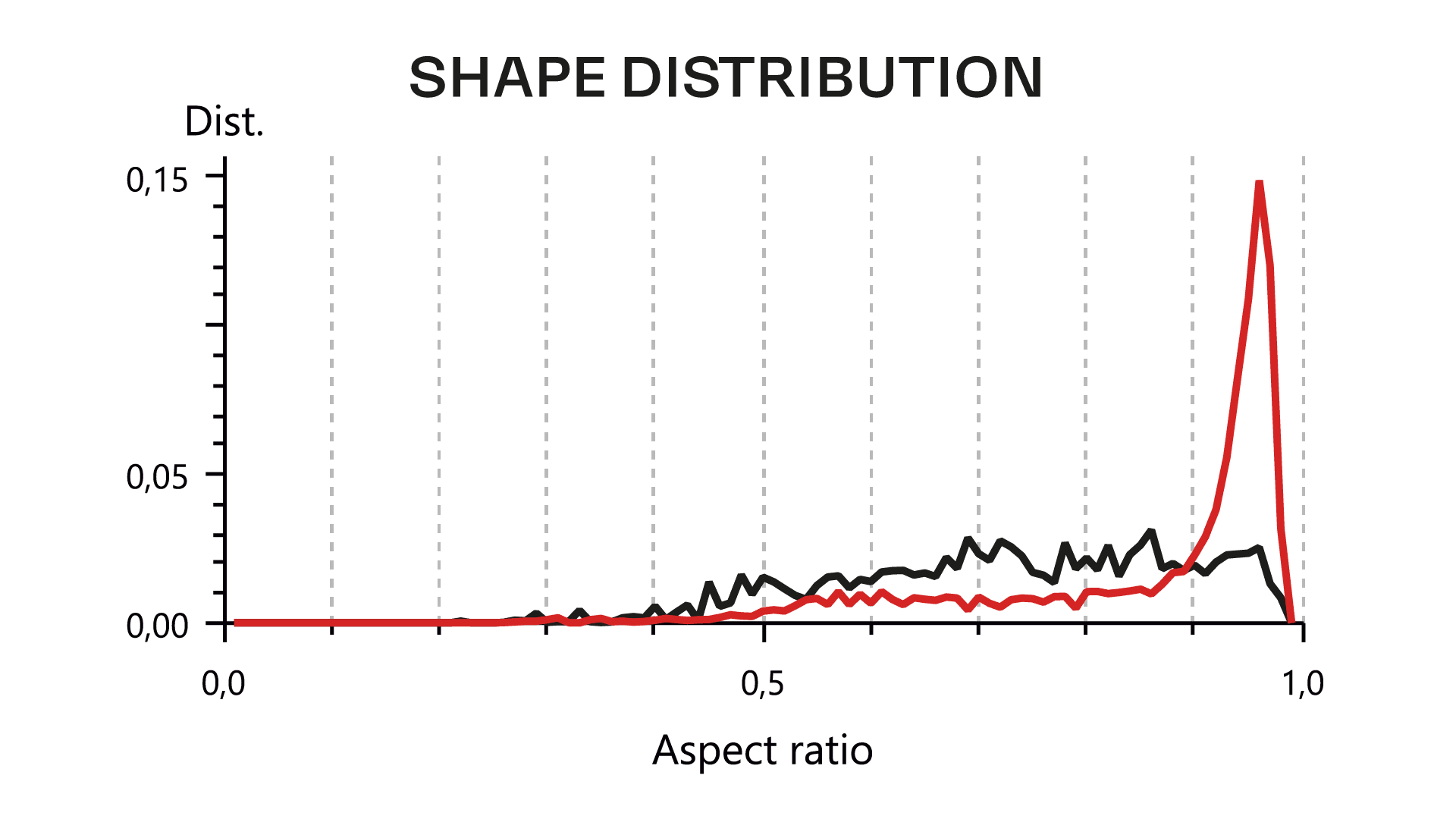

Particle Size

Distribution

MATERIAL

Ti64

Limited to printing

with non-spherical powders?

SEM

IMAGES

Particle Size

Distribution